- History & Society

- Science & Tech

- Biographies

- Animals & Nature

- Geography & Travel

- Arts & Culture

- Games & Quizzes

- On This Day

- One Good Fact

- New Articles

- Lifestyles & Social Issues

- Philosophy & Religion

- Politics, Law & Government

- World History

- Health & Medicine

- Browse Biographies

- Birds, Reptiles & Other Vertebrates

- Bugs, Mollusks & Other Invertebrates

- Environment

- Fossils & Geologic Time

- Entertainment & Pop Culture

- Sports & Recreation

- Visual Arts

- Demystified

- Image Galleries

- Infographics

- Top Questions

- Britannica Kids

- Saving Earth

- Space Next 50

- Student Center

Toyota Motor Corp. summary

Toyota Motor Corp. , Largest Japanese automobile manufacturer and one of the largest automotive companies in the world. It was established in 1933 as a division of the Toyoda Automatic Loom Works, Ltd., and in 1937 it was incorporated as the Toyota Motor Co., Ltd. Toyota later established many related companies, including Toyoda Machine Works, Ltd. (1941), and Toyota Auto Body, Ltd. (1945). In the 1960s and ’70s the company expanded rapidly, exporting large numbers of cars to foreign markets. Following consolidations among many of its business units, the company took the name Toyota Motor Corp. in 1982. It has assembly plants and distributors in many foreign countries, and it owns subsidiaries that produce cars and car parts, trucks, steel, synthetic resins, and industrial equipment. Its brands include Toyota and Lexus.

The Evolution of Toyota in Automotive History: From Humble Beginnings to Global Dominance

Table of Contents

I. Introduction

Toyota holds immense significance in the automotive industry, known for innovation, reliability, and transformative impact. This article explores Toyota’s rich history, tracing its origins from a textile machinery company to a global automotive powerhouse. It examines the evolution of Toyota’s pioneering contributions, including hybrid technology and the Toyota Production System (TPS). Moreover, the article delves into Toyota’s commitment to sustainability, social responsibility, and its ambitious vision for the future of mobility.

II. Origins and Founding

A. the early beginnings of toyota as a textile machinery company.

Toyota’s origins can be traced back to the Toyoda Automatic Loom Works, a textile machinery company founded by Sakichi Toyoda in 1926. Sakichi Toyoda was a prolific inventor and entrepreneur who revolutionized the textile industry with his innovative power loom designs. His inventions laid the foundation for the rapid growth of the company and established the Toyoda name as a symbol of engineering excellence.

B. Kiichiro Toyoda’s Vision for Entering the Automotive Market

Kiichiro Toyoda, the son of Sakichi Toyoda, shared his father’s spirit of innovation and aspired to expand the family business beyond textile machinery. Recognizing the potential of the burgeoning automotive industry, Kiichiro envisioned a new venture: building automobiles. His vision was fueled by a desire to contribute to Japan’s industrial development and meet the growing demand for cars in the country.

Kiichiro Toyoda understood that automobile manufacturing required a different set of skills and expertise from textile machinery production. To turn his vision into reality, he sent a team of engineers to the United States and Europe to study automotive manufacturing techniques and technology. This endeavour was crucial in equipping Toyota with the knowledge and expertise needed to enter the competitive automotive market.

C. The Establishment of Toyota Motor Corporation

Inspired by the lessons learned from overseas research, Kiichiro Toyoda laid the groundwork for establishing Toyota Motor Corporation. On August 28, 1937, the company was officially founded, and it would go on to become one of the most significant names in the global automotive industry.

The name “Toyota” was chosen for the new venture, as it was considered more auspicious than “Toyoda” when written in Japanese characters. The change also reflected the company’s aspiration to create a new identity distinct from its textile machinery origins.

With a strong commitment to quality and innovation, Toyota Motor Corporation set out on its automotive journey. The company’s first passenger car, the Model AA, was introduced in 1936, marking the beginning of Toyota’s evolution into a leading automobile manufacturer.

From its humble beginnings as a textile machinery company to the establishment of Toyota Motor Corporation, this pivotal phase in Toyota’s history laid the foundation for the brand’s enduring legacy and global influence in the automotive industry. The vision of Kiichiro Toyoda, combined with the spirit of innovation inherited from Sakichi Toyoda, set Toyota on a path of innovation and excellence that continues to define the brand to this day.

III. The Pre-War Years

A. toyota’s first passenger car: the model aa.

In 1936, Toyota Motor Corporation made a significant stride by introducing its first passenger car, the Model AA. The Model AA was an embodiment of Toyota’s commitment to quality and engineering prowess. Inspired by American and European automobile designs, the Model AA boasted a sleek and sophisticated appearance, setting it apart from other vehicles of its time.

The Model AA featured a robust 3.4-litre inline-six engine, delivering 62 horsepower, and could reach a top speed of 100 kilometres per hour (approximately 62 miles per hour), a remarkable achievement for that era. It’s innovative design and reliable performance garnered positive attention from consumers and established Toyota as a serious contender in the automotive market.

B. Navigating Challenges During World War II

As Japan became embroiled in World War II, the automotive industry faced a tumultuous period marked by resource shortages and shifting priorities. Toyota, like other automakers, had to adapt to the demands of war production. During this time, the company shifted its focus from civilian vehicles to manufacturing military trucks and equipment to support the war effort.

Despite the challenging circumstances, Toyota demonstrated resilience and resourcefulness, meeting wartime demands with determination. This experience would shape the company’s ability to innovate and adapt to changing circumstances in the years to come.

C. Post-War Recovery and Rebuilding

Following the end of World War II, Japan faced the arduous task of rebuilding its economy and infrastructure. Toyota, too, had to navigate the challenges of post-war recovery. With limited resources and facilities damaged during the war, the company faced an uphill battle to resume automobile production.

In the early post-war years, Toyota focused on producing commercial vehicles to contribute to Japan’s reconstruction efforts. The company’s commitment to efficiency and quality allowed it to regain momentum and reestablish itself in the domestic market.

As Japan experienced an economic boom in the 1950s and 1960s, Toyota seized the opportunity to expand its reach beyond Japan’s borders. The company began exporting vehicles, starting with the Toyopet Crown, to international markets, primarily to the United States.

By the end of the 1950s, Toyota had solidified its position as one of Japan’s leading automakers. Its dedication to continuous improvement, quality manufacturing, and innovative engineering practices laid the groundwork for the brand’s future success.

The pre-war years were a transformative period for Toyota, witnessing the company’s early foray into passenger car production with the Model AA and its ability to endure and adapt during the challenges of World War II. Through post-war recovery and a focus on quality and efficiency, Toyota positioned itself for further growth and international expansion in the years to come. These formative experiences would shape Toyota’s identity as a resilient and innovative automotive powerhouse, setting the stage for its enduring impact on the global automotive landscape.

IV. Expansion and International Presence

A. toyota’s export ventures and success in the u.s. market.

In the 1950s, Toyota embarked on a bold venture to expand its presence beyond Japan’s shores. The United States, with its vast market and growing appetite for compact and fuel-efficient cars, became a key target for Toyota’s international ambitions.

In 1957, Toyota officially entered the U.S. market with the introduction of the Toyopet Crown, aiming to compete with established American automakers. However, the Toyopet faced challenges in the U.S., as it was not well-suited to the preferences and driving conditions of American consumers. Despite this setback, Toyota persevered and recognized the need to adapt to the unique demands of the U.S. market.

The turning point came in 1965 with the introduction of the Toyota Corona. The Corona was meticulously designed to meet the requirements of American consumers, featuring a more spacious interior, improved performance, and higher fuel efficiency. Corona’s success established Toyota as a formidable player in the U.S. automotive landscape, setting the stage for its future growth and acceptance in the American market.

B. Innovation and Introduction of Iconic Models (e.g., Land Cruiser and Corolla)

As Toyota’s international presence expanded, the company continued to demonstrate its commitment to innovation and engineering excellence through the introduction of iconic models that would become synonymous with reliability and performance.

The Toyota Land Cruiser, initially introduced in 1951 as a rugged utility vehicle, earned a reputation for its off-road capabilities and durability. It became a preferred choice for challenging terrains and exploration, solidifying Toyota’s reputation for building vehicles that could withstand demanding conditions.

Another groundbreaking model was the Toyota Corolla, introduced in 1966. The Corolla quickly gained popularity worldwide, becoming one of the best-selling cars in history. Its exceptional fuel efficiency, practical design, and affordability appealed to a broad range of consumers, contributing significantly to Toyota’s global success.

C. Establishing Production Plants Worldwide

With growing international demand for Toyota vehicles, the company made strategic decisions to establish production plants outside of Japan. By the 1980s, Toyota had set up manufacturing facilities in various countries, including the United States, Canada, the United Kingdom, Australia, and other parts of Asia.

Local production not only allowed Toyota to cater to regional preferences and reduce import costs but also fostered a deeper connection with local communities. The establishment of these production plants marked Toyota’s commitment to becoming a global enterprise with a “think globally, act locally” approach.

Furthermore, Toyota’s emphasis on lean manufacturing principles, as inspired by the Toyota Production System, became the blueprint for efficient and high-quality production worldwide. The company’s continuous pursuit of excellence in manufacturing processes further solidified its reputation for reliability and quality in international markets.

V. Toyota’s Production System and Quality Revolution

A. the birth of the toyota production system (tps).

The foundation of Toyota’s success lies in the revolutionary Toyota Production System (TPS), which originated in the 1940s and 1950s. Developed by Taiichi Ohno, Shigeo Shingo, and other Toyota engineers, TPS aimed to eliminate waste, increase efficiency, and improve overall productivity.

One of the key principles of TPS is “jidoka,” which refers to the concept of automation with a human touch. This principle empowers workers to stop the production line when a defect is detected, allowing for immediate correction and preventing faulty products from continuing down the line. This emphasis on quality control and problem-solving at the source became a defining feature of TPS.

B. Implementing “Just-In-Time” Manufacturing and Lean Principles

Central to TPS is the “Just-In-Time” (JIT) manufacturing system. JIT emphasizes producing only what is needed when it is needed, and in the required quantity. This approach minimizes inventory and reduces the carrying costs associated with excess stock. By synchronizing production with customer demand, Toyota improved efficiency, reduced lead times, and minimized waste.

Incorporating lean principles, TPS emphasizes continuous improvement and the elimination of any activity that does not add value to the final product. The “5S” methodology, focusing on sorting, setting in order, shining, standardizing, and sustaining, became the basis for creating organized and efficient workplaces.

Furthermore, TPS encourages a culture of employee engagement, where all team members are encouraged to contribute ideas and participate in problem-solving activities. This participatory approach to continuous improvement has been fundamental to Toyota’s ability to stay ahead in a rapidly changing automotive landscape.

C. Earning a Reputation for Quality and Reliability

The implementation of TPS and JIT manufacturing revolutionized Toyota’s production process, leading to significant improvements in quality and reliability. By minimizing defects, improving efficiency, and reducing lead times, Toyota was able to produce vehicles of consistently high quality.

Toyota’s commitment to quality was further solidified by the introduction of the “Toyota Way,” a set of guiding principles encompassing continuous improvement, respect for people, and long-term thinking. This customer-centric approach ensured that the focus remained on delivering value to customers and exceeding their expectations.

As a result of these efforts, Toyota gained a reputation for producing vehicles that were reliable, durable, and built to high standards. Consumers came to trust Toyota as a brand associated with quality and dependability, which significantly contributed to the company’s global success.

- Womack, James P. (Author)

- English (Publication Language)

- 352 Pages – 03/13/2007 (Publication Date) – Free Press (Publisher)

- successful business

- how to run business

- Toyota company story

- Hardcover Book

- Liker, Jeffrey (Author)

- 330 Pages – 01/07/2004 (Publication Date) – McGraw Hill (Publisher)

- LIKER (Author)

- 481 Pages – 04/19/2011 (Publication Date) – McGraw Hill (Publisher)

- Anderson, Katie (Author)

- 350 Pages – 07/14/2020 (Publication Date) – Integrand Press (Publisher)

- Used Book in Good Condition

- Taiichi Ohno (Author)

- 152 Pages – 03/01/1988 (Publication Date) – Productivity Press (Publisher)

- Liker, Jeffrey K. (Author)

- 448 Pages – 12/01/2020 (Publication Date) – McGraw Hill (Publisher)

Last update on 2024-09-13 / Affiliate links / Images from Amazon Product Advertising API

VI. Embracing Hybrid Technology

A. pioneering hybrid technology with the prius.

In 1997, Toyota made a groundbreaking move in the automotive industry by introducing the world’s first mass-produced hybrid car, the Toyota Prius. The Prius was the culmination of Toyota’s vision for sustainable mobility, combining an internal combustion engine with an electric motor powered by a battery pack. This innovative hybrid system allowed the Prius to run on both gasoline and electricity, reducing fuel consumption and emissions.

The development of the Prius was not without its challenges. Toyota faced scepticism from the industry and consumers alike, as hybrid technology was largely untested and unfamiliar at the time. However, Toyota’s commitment to environmentally friendly technology and its pioneering spirit led the company to invest in hybrid research and development.

B. The Impact of Prius on the Automotive Industry

The launch of the Toyota Prius had a profound impact on the automotive industry, reshaping the way car manufacturers and consumers viewed eco-friendly vehicles. The Prius demonstrated that hybrid technology was not only viable but also capable of becoming a mainstream solution for reducing emissions and fuel consumption.

The success of the Prius served as a catalyst for other automakers to invest in hybrid technology and alternative fuel vehicles. As a result, hybrid cars proliferated in the automotive market, providing consumers with more eco-conscious choices and driving advancements in electric and hybrid technology.

Moreover, the Prius became a symbol of Toyota’s commitment to innovation and sustainability. It showcased Toyota’s ability to deliver on its promise of environmental responsibility while providing consumers with practical and efficient vehicles.

C. Toyota’s Commitment to Sustainable Mobility

The introduction of the Prius was just the beginning of Toyota’s commitment to sustainable mobility. As one of the pioneers in hybrid technology, Toyota continued to refine and expand its hybrid lineup, offering hybrid versions of popular models across various vehicle segments.

Toyota’s dedication to sustainable mobility extended beyond hybrids to include plug-in hybrid electric vehicles (PHEVs) and hydrogen fuel cell vehicles (FCVs). The company launched models like Prius Prime and Mirai, further solidifying its position as a leader in eco-friendly technologies.

Beyond the development of eco-friendly vehicles, Toyota invested in research and development of advanced battery technologies and explored ways to reduce the environmental impact of its manufacturing processes. The company’s focus on recycling and waste reduction demonstrated its commitment to a more sustainable future.

Toyota’s efforts towards sustainable mobility were not limited to product innovation. The company actively engaged in environmental initiatives and partnerships, advocating for clean energy and supporting global efforts to combat climate change.

VII. Advancements in Technology and Safety

A. toyota’s research and development in cutting-edge technology.

Throughout its history, Toyota has been at the forefront of research and development, continually pushing the boundaries of automotive technology. The company’s commitment to innovation has led to significant advancements in various areas, including engine efficiency, materials science, and electronics.

Toyota’s research efforts have resulted in the development of more fuel-efficient engines, such as the advanced Variable Valve Timing (VVT-i) system, which optimizes engine performance while reducing emissions. Additionally, the company’s work in materials science has led to the use of lightweight materials like high-strength steel and carbon fibre composites, enhancing vehicle fuel efficiency and overall performance.

Furthermore, Toyota’s focus on electronics and connectivity has given rise to smart features, such as infotainment systems, advanced driver-assistance systems (ADAS), and sophisticated telematics that provide real-time data and enhance the driving experience.

B. Introduction of Advanced Safety Features and Autonomous Driving

Safety has always been a top priority for Toyota, and the company has been a trailblazer in introducing advanced safety features to its vehicles. Toyota’s commitment to “safety for all” is embodied in its Toyota Safety Sense (TSS) suite of technologies, which includes features like pre-collision systems, lane departure alerts, adaptive cruise control, and automatic high beams. These technologies enhance driver safety and help prevent accidents, making driving safer for both occupants and pedestrians.

Moreover, Toyota has been actively working on autonomous driving technology to improve road safety and driver convenience. The company’s research in this field has led to the development of Level 2 advanced driver-assistance systems, which offer functions like lane-centering and hands-free driving in specific conditions. Toyota continues to invest in autonomous driving research with the goal of achieving higher levels of automation in the future.

C. Toyota’s Contributions to the Future of Mobility

As the automotive industry undergoes a paradigm shift towards sustainable and connected mobility, Toyota has positioned itself as a major contributor to shaping the future of transportation.

Toyota’s commitment to sustainable mobility is evident in its efforts to expand its lineup of electrified vehicles. In addition to hybrids and plug-in hybrids, Toyota is actively developing battery electric vehicles (BEVs) and hydrogen fuel cell electric vehicles (FCEVs). The company’s Mirai model, powered by hydrogen fuel cells, represents Toyota’s vision for a zero-emission future.

Beyond individual vehicles, Toyota is exploring mobility solutions that extend beyond traditional car ownership. The company is engaged in projects related to mobility-as-a-service (MaaS), car-sharing, and smart city initiatives, aiming to provide seamless and sustainable transportation solutions for urban environments.

Furthermore, Toyota’s collaborative approach with technology partners and start-ups has resulted in joint ventures and partnerships to drive innovation in areas like connected vehicles, artificial intelligence, and mobility platforms. These efforts reflect Toyota’s commitment to staying at the cutting edge of technology and advancing the future of mobility.

VIII. Social Responsibility and Environmental Initiatives

A. toyota’s efforts towards environmental sustainability.

As a global leader in the automotive industry, Toyota recognizes its responsibility to address environmental challenges and minimize its ecological footprint. The company has been actively implementing various initiatives to promote environmental sustainability throughout its operations.

- Eco-Friendly Vehicles: Toyota’s commitment to sustainable mobility is evident in its development and promotion of eco-friendly vehicles. Beyond hybrids, the company has expanded its lineup to include plug-in hybrids, battery electric vehicles (BEVs), and hydrogen fuel cell electric vehicles (FCEVs). By offering a diverse range of electrified options, Toyota seeks to contribute to reducing greenhouse gas emissions and promoting cleaner transportation.

- Lightweight Materials and Recycling: Toyota has focused on reducing the weight of its vehicles through the use of lightweight materials, which improves fuel efficiency and lowers emissions. Additionally, the company emphasizes recycling and reducing waste throughout its manufacturing processes, demonstrating a commitment to responsible resource management.

- Green Manufacturing: Toyota aims to minimize the environmental impact of its production facilities by adopting green manufacturing practices. The company invests in energy-efficient technologies and renewable energy sources to reduce carbon emissions and water consumption.

B. Corporate Social Responsibility Programs and Community Engagement

Toyota’s commitment to social responsibility extends beyond environmental initiatives to encompass various programs and initiatives that positively impact communities and society at large.

- Education and Skill Development: Toyota actively supports education and skill development programs to empower individuals and communities. Initiatives include scholarships, vocational training programs, and collaborations with educational institutions to foster learning and skill enhancement.

- Disaster Relief and Humanitarian Aid: In times of natural disasters or humanitarian crises, Toyota is quick to lend support through financial assistance, material donations, and the deployment of volunteers. The company has a track record of providing aid and relief efforts in affected regions around the world.

- Community Engagement: Toyota emphasizes community engagement by actively participating in local activities and promoting initiatives that benefit the well-being of communities. This includes sponsoring local events, supporting cultural initiatives, and collaborating with community-based organizations.

C. Aligning with the United Nations Sustainable Development Goals (SDGs)

Toyota has aligned its corporate strategy and initiatives with the United Nations Sustainable Development Goals (SDGs), a set of global targets aimed at addressing social, environmental, and economic challenges.

- Goal 7: Affordable and Clean Energy – Toyota’s efforts to develop alternative energy vehicles, including hybrids, BEVs, and FCEVs, align with the goal of promoting clean and sustainable energy sources for transportation.

- Goal 9: Industry, Innovation, and Infrastructure – Toyota’s focus on research and development, innovation in automotive technology, and green manufacturing contributes to the advancement of sustainable industry and infrastructure.

- Goal 12: Responsible Consumption and Production – Through its commitment to recycling, reducing waste, and sustainable manufacturing practices, Toyota contributes to responsible consumption and production patterns.

- Goal 13: Climate Action – Toyota’s efforts to reduce vehicle emissions, develop low-carbon technologies, and promote sustainable mobility align with the goal of taking urgent action to combat climate change.

IX. Challenges and Recalls

A. the challenges faced by toyota, including recalls.

Despite Toyota’s reputation for quality and reliability, the company faced significant challenges over the years, including high-profile recalls. One notable recall incident occurred in 2009-2010 when millions of Toyota vehicles were recalled due to issues related to unintended acceleration. This raised concerns about the safety and reliability of Toyota vehicles, tarnishing the brand’s image and eroding consumer trust.

The recall crisis put Toyota under intense scrutiny, both from regulatory authorities and the public. It also resulted in numerous lawsuits, financial penalties, and a damaged reputation for the company, which had prided itself on its commitment to quality and customer safety.

B. Toyota’s Response to Safety Issues and Rebuilding Trust

In response to the recall crisis, Toyota took swift and comprehensive actions to address safety issues, enhance quality control, and regain consumer trust. The company established a special committee to investigate the problems and implemented measures to prevent similar incidents in the future.

Toyota showed transparency and accountability by promptly communicating with customers about the recalls and providing detailed information on the actions being taken to rectify the issues. The company strengthened its relationships with regulatory agencies and worked closely with them to ensure that all necessary safety improvements were made.

To address safety concerns and rebuild trust, Toyota launched a “Customer First” initiative, emphasizing a renewed focus on customer satisfaction, safety, and quality. The company also enhanced its internal communication and problem-reporting mechanisms to ensure that potential issues were identified and addressed promptly.

C. Lessons Learned and Continuous Improvement

The recall crisis served as a profound learning experience for Toyota. The company recognized the importance of continuous improvement in its processes, safety protocols, and quality assurance systems. Toyota redoubled its efforts to create a culture of open communication, encouraging employees at all levels to report potential problems and offer suggestions for improvement.

Toyota also invested in research and development to develop new safety technologies and further enhance the safety features of its vehicles. The company actively collaborated with safety regulators and industry peers to share best practices and contribute to the establishment of industry-wide safety standards.

Through this challenging period, Toyota reaffirmed its commitment to putting the safety and satisfaction of customers first. The company implemented rigorous testing and evaluation procedures to ensure that every vehicle met the highest standards of safety and quality before being released to the market.

X. Toyota’s Global Dominance and Future Vision

A. toyota’s position as one of the world’s largest automotive manufacturers.

Toyota’s relentless pursuit of excellence and innovation has solidified its position as one of the world’s largest and most influential automotive manufacturers . Over the years, Toyota has consistently ranked among the top global automakers in terms of vehicle sales and market share.

The company’s diverse product portfolio, which includes sedans, SUVs, trucks, hybrids, and electric vehicles, caters to a wide range of consumer preferences and market segments. Toyota’s reputation for producing reliable, fuel-efficient, and technologically advanced vehicles has earned it the loyalty of millions of customers worldwide.

Additionally, Toyota’s global presence extends to every continent, with manufacturing plants and sales networks spanning multiple countries. The company’s commitment to local production enables it to cater to regional demands, foster economic growth in host countries, and create employment opportunities for local communities.

B. The Company’s Vision for the Future of Mobility and Innovation

Looking ahead, Toyota’s vision for the future of mobility is underpinned by its commitment to sustainable and connected transportation solutions. The company envisions a future where mobility is not only environmentally responsible but also seamless and convenient for consumers.

Toyota is actively investing in research and development to further advance alternative fuel technologies, including hydrogen fuel cell vehicles and solid-state batteries for electric vehicles. The company continues to refine its hybrid and plug-in hybrid offerings, aiming to make electrified vehicles accessible to a broader audience.

Moreover, Toyota is at the forefront of autonomous driving research, focusing on developing self-driving technologies that prioritize safety and enhance the driving experience. By leveraging artificial intelligence and data analytics, Toyota aims to create a new era of mobility that is safer, more efficient, and personalized to individual needs.

C. Toyota’s Enduring Legacy in the Automotive Industry

Toyota’s enduring legacy in the automotive industry is rooted in its commitment to “kaizen” – continuous improvement. The company’s emphasis on quality, efficiency, and innovation has set the benchmark for manufacturing processes and management practices across the automotive sector.

Furthermore, Toyota’s contribution to sustainability and environmental responsibility has made it a role model for other companies seeking to reduce their carbon footprint and embrace eco-friendly technologies.

Beyond its technological prowess, Toyota’s legacy is also reflected in its corporate culture and values. The company places a strong emphasis on integrity, respect for people, and social responsibility, aligning its business practices with the well-being of society and the environment.

As Toyota continues to adapt to changing consumer preferences and evolving industry trends, its legacy of resilience, innovation, and customer-centric approach will remain foundational to its future success.

XI. Conclusion

A. recap of toyota’s transformative journey and contributions.

Toyota’s journey through automotive history has been nothing short of transformative. From its humble beginnings as a textile machinery company to becoming one of the world’s largest automotive manufacturers, Toyota’s rise to prominence has been marked by innovation, resilience, and a commitment to excellence.

Throughout its history, Toyota has pioneered numerous advancements in automotive technology, setting new industry standards and influencing competitors worldwide. From the introduction of the revolutionary Toyota Production System (TPS) to the pioneering development of hybrid technology with the Prius, Toyota has consistently pushed the boundaries of what is possible in the automotive world.

Toyota’s contributions go beyond technological innovations. The company’s dedication to safety, environmental sustainability, and social responsibility has made it a role model for responsible corporate practices. Toyota’s commitment to quality and customer satisfaction has earned it the loyalty and trust of millions of customers around the globe.

B. Final Remarks on Toyota’s Ongoing Impact and Continued Success

As Toyota looks to the future, its impact on the automotive industry and society at large remains significant. The company’s vision for sustainable mobility, embracing electric and hydrogen-powered vehicles, and investing in autonomous driving technologies positions it as a key player in shaping the future of transportation.

Toyota’s legacy extends far beyond its commercial success; it reflects a deep-rooted culture of innovation, a dedication to customer needs, and a commitment to making a positive impact on the world. Toyota’s ongoing success lies not only in its ability to adapt to changing market dynamics but also in its unwavering commitment to its core values.

With a continued focus on continuous improvement, Toyota is poised to remain a driving force in the automotive industry. Its legacy of reliability, quality, and technological innovation will continue to set it apart and inspire the next generation of automakers.

In conclusion, Toyota’s transformative journey from a textile machinery company to a global automotive powerhouse is a testament to the power of innovation, determination, and a customer-centric approach. As Toyota continues to shape the future of mobility, its enduring legacy as a trailblazer in the automotive industry will continue to inspire and leave a lasting impact on the world. With its focus on sustainability, innovation, and customer satisfaction, Toyota is poised to lead the way in creating a more sustainable and connected future for generations to come.

Gregory Baker is a passionate automotive writer and enthusiast who captivates readers with his engaging articles. As a valued member of the Motorcar Central team, Gregory offers readers an exciting opportunity to explore the world of motorcars. With his deep affection for cars, he immerses himself in the automotive realm, seeking new experiences and insights to share with his audience.

Similar Posts

BMW: A Legacy of Innovation and Driving Pleasure

Affiliate Disclosure: Some links on this page are affiliate links which means that, if you choose…

Top 10 Car Brands: A Comprehensive Comparison 2023

The Rise of Hyundai: A Journey through History

SAIC Motor Corporation: Driving Towards Excellence – A Historical Journey

From Pioneers to Innovators: The Evolution of Daimler AG in Automotive History

Evolution of Nissan: A Journey through Automotive History

Home — Essay Samples — Business — Toyota — The History Of Development Of Toyota Company

The History of Development of Toyota Company

- Categories: Automobile Company Toyota

About this sample

Words: 987 |

Published: Jan 21, 2020

Words: 987 | Pages: 2 | 5 min read

Bibliography

- Toyota More Corporation Global Website. https://www.toyota-global.com/Toyota Code of Conduct. https://www.toyota-global.com/company/vision_philosophy/toyota_code_of_conduct.html /

- Nudd, Tim. (2018). Emotional Ads. https://www.adweek.com/creativity/toyotas-good-odds-is-called-the-most-effective-super-bowl-ad-on-key-brand-metrics/

- Allen, Katie. & Sturcke, James. (2010). Timeline: Toyota's recall woes. https://www.theguardian.com/business/2010/jan/29/timeline-toyota-recall-accelerator-pedal

- Toyota Whitepapers. https://www.toyotaforklift.com/resource-library/whitepapers

- Relationship with Our Local Communities. https://www.toyota-industries.com/csr/management/local/

- Montpetit, Helena. (2014, Oct 14). “You, asked for it. You got it.” Toyota on social media. https://smbp.uwaterloo.ca/2014/10/you-asked-for-it-you-got-it-toyota-on-social-media/

- Takahashi, Yoshio. & Shirouzu, Norihiko. (2010, Feb 6). Toyota Apologizes for Massive Recall. https://www.wsj.com/articles/SB10001424052748704533204575046581311548918

- McCurry, Justin. (2010, Feb 5). Toyota president Akio Toyoda 'very sorry' for safety recalls. https://www.theguardian.com/business/2010/feb/05/toyota-president-very-sorry-recalls [bookmark: _Hlk525783828]

- Hemus, Jonathan. (2010, Feb 9). Accelerating towards crisis: a PR view of Toyota's recall. https://www.theguardian.com/business/2010/feb/09/pr-view-toyota-reputation-management

- Shimizu, Norihiko. & Osono, Emi. & Takeuchi, Hirotaka. (2008, June) The Contradictions That Drive Toyota’s Success. https://hbr.org/2008/06/the-contradictions-that-drive-toyotas-success

- Toyota’s vision sets the wheels of society in motion. https://www.salesforce.com/customer-success-stories/toyota/

Cite this Essay

To export a reference to this article please select a referencing style below:

Let us write you an essay from scratch

- 450+ experts on 30 subjects ready to help

- Custom essay delivered in as few as 3 hours

Get high-quality help

Verified writer

- Expert in: Science Business

+ 120 experts online

By clicking “Check Writers’ Offers”, you agree to our terms of service and privacy policy . We’ll occasionally send you promo and account related email

No need to pay just yet!

Related Essays

8 pages / 3788 words

3 pages / 1195 words

1 pages / 624 words

4 pages / 1950 words

Remember! This is just a sample.

You can get your custom paper by one of our expert writers.

121 writers online

Still can’t find what you need?

Browse our vast selection of original essay samples, each expertly formatted and styled

Related Essays on Toyota

Honda Rivalry Among Competitors: Strong Force. Competition in the automobile industries is very high, as there are many firms in this industry that caters to many varieties of customers, so each firm try to do its best to make [...]

The Toyota Motor Sales U.S.A., Inc. Mission and Vision Statements are as follows: Mission Statement: "To attract and attain customers with outstanding products and services and the most satisfying ownership experience in [...]

Toyota products were in high demand worldwide and they had a time when they felt they might not be able to meet the demand of customers but they were selling as normal routine and increase the production with huge volumes and [...]

Toyota has built a huge manufacturing company that can produce millions of cars each year for a wide variety of consumers, is able to grow so much bigger than any other auto manufacturer because it provides cars that contain [...]

Starship Technologies sounded the starting weapon to set up self-administering transport vehicles available to be purchased to the general population with a $17.2 million round drove by Daimler back in January 2017. By then in [...]

Two legs on a white background. One is a familiar human leg of flesh and bone. The other is a black prosthetic with a metal band around the ankle and manufacture sticker below. The foot is cream colored and attempts to replicate [...]

Related Topics

By clicking “Send”, you agree to our Terms of service and Privacy statement . We will occasionally send you account related emails.

Where do you want us to send this sample?

By clicking “Continue”, you agree to our terms of service and privacy policy.

Be careful. This essay is not unique

This essay was donated by a student and is likely to have been used and submitted before

Download this Sample

Free samples may contain mistakes and not unique parts

Sorry, we could not paraphrase this essay. Our professional writers can rewrite it and get you a unique paper.

Please check your inbox.

We can write you a custom essay that will follow your exact instructions and meet the deadlines. Let's fix your grades together!

Get Your Personalized Essay in 3 Hours or Less!

We use cookies to personalyze your web-site experience. By continuing we’ll assume you board with our cookie policy .

- Instructions Followed To The Letter

- Deadlines Met At Every Stage

- Unique And Plagiarism Free

Toyota Company Essays

Disruptive marketing plan, strategic operation management: lean philosophy and the theory of swift even flow, popular essay topics.

- American Dream

- Artificial Intelligence

- Black Lives Matter

- Bullying Essay

- Career Goals Essay

- Causes of the Civil War

- Child Abusing

- Civil Rights Movement

- Community Service

- Cultural Identity

- Cyber Bullying

- Death Penalty

- Depression Essay

- Domestic Violence

- Freedom of Speech

- Global Warming

- Gun Control

- Human Trafficking

- I Believe Essay

- Immigration

- Importance of Education

- Israel and Palestine Conflict

- Leadership Essay

- Legalizing Marijuanas

- Mental Health

- National Honor Society

- Police Brutality

- Pollution Essay

- Racism Essay

- Romeo and Juliet

- Same Sex Marriages

- Social Media

- The Great Gatsby

- The Yellow Wallpaper

- Time Management

- To Kill a Mockingbird

- Violent Video Games

- What Makes You Unique

- Why I Want to Be a Nurse

- Send us an e-mail

- Call to +1 844 889-9952

Toyota Operations Management & Demand Forecasting

| 📄 Words: | 2856 |

|---|---|

| 📝 Subject: | |

| 📑 Pages: | 11 |

| 💼 Companies: |

Introduction

- Toyota Overview

Toyota Operations & Processes

The house of quality technique.

- Competitiveness of Toyota

- Toyota Vs. Nissan Competitiveness

- Toyota Supply Chain

Toyota Forecasting Methods

Effective operations management is critical for the success of any organisation because it determines and regulates all processes in the company, influencing the quality of products and services. Toyota Motor Corporation is an example of a company that pays close attention to organising its operations and supply chain while remaining a leader in the automotive industry.

The purpose of this report is to present an overview of Toyota’s products and strategies, describe its micro-operations and processes, discuss the application of the House of Quality technique to an analysis of the company’s products, describe Toyota’s competitive capabilities, and compare them with other companies in the automotive industry. Additionally, this report will provide a discussion of the supply chain and illustrate an application of an approach to forecasting demand for the company.

Overview of Toyota: Products, Environments, Strengths, and Weaknesses

Toyota was founded by Kiichiro Toyoda in Japan in 1937, and today this multinational manufacturer of vehicles holds sixth place among the largest companies with the highest revenues in the world. Toyota’s revenue for 2018 was $265 billion, and the current number of employees is more than 360,000 worldwide (Toyota USA, 2019). Presently, the company produces about 10 million cars per year, including hybrid cars (Toyota, 2018).

Still, Toyota’s variety of products is represented not only by vehicles (sedans, minivans, coupes, liftbacks, crossovers, and trucks) but also by automobile engines, as well as car electronics and compressors, along with textile machinery. Currently, Toyota is focused on increasing the market share of the company’s hybrid electric vehicles in order to preserve its position as a leader in this sector.

The modern environment of the automotive industry in which Toyota operates is characterised by manufacturers’ focus on technologies, innovation, diversification, and sustainability. These aspects are among the most important ones that must be taken into account when developing a company’s strategy. Companies’ opportunities in the present environment are associated with possibilities to design and implement the latest technologies in order to increase sustainability and attract more customers (Bhattacharya, 2014). The focus is also on the further growth of the market for hybrid electric vehicles.

Still, threats in this area include the intense competition between rival companies, frequent changes in oil prices and their impact on the industry, and consumers becoming more interested in economically advantageous cars, including hybrid and electric vehicles (Bhattacharya, 2014; Toyota, 2018). In addition, the rise of the Chinese automotive industry has been observed in recent years, which is also influencing the global market.

However, it is also important to mention Toyota’s specific strengths and weaknesses that affect its strategy, operations, and position in the market. Toyota is interested in applying the principles of innovation to different processes, including research and development (R&D), the manufacturing process, and even corporate culture. The focus on R&D allows the company to remain a pioneer in the industry through applying the most innovative technologies (Bhattacharya, 2014). The company spends about $9 billion on R&D each year and regularly develops new models and variants of vehicles, as well as improvements on existing models (Toyota, 2018).

In addition, the company is characterised by high customer loyalty and wide brand recognition. The company’s vehicles have a good reputation among consumers because of their safety, design, and innovative technologies. Weaknesses associated with Toyota’s operations and products are mainly related to incidents that led to the recalls of vehicles in recent years (Toyota, 2018; Toyota USA, 2019). This has affected consumers’ attitudes towards the brand and sales because of safety issues.

The process of manufacturing vehicles should be discussed as a macro-process, or a macro-level consisting of a range of micro-operations. Moreover, for Toyota, manufacturing involves the participation of many different suppliers who are responsible for producing certain parts of its vehicles. The process of completing a car also includes several important micro-levels of operations. For example, at the stage of creating a product design, micro-operations include the development of a cost-efficient but innovative draft design, the discussion of this design, its approval, and the development of test models or prototypes.

At the stage of producing car components, processes include manufacturing parts and components according to schemes and models addressing the standardised tasks and their further control and testing (Bhattacharya, 2014; Gao & Low, 2014). In addition, it is important to note that Toyota’s overall production process is guided by the company’s philosophy of lean manufacturing.

The company is focused on optimising the production process in order to address inventory and storage issues to reduce the time that manufactured parts are stored, as well as to decrease the associated man-hours. These principles are used in the context of the company’s operations strategy (Lean Production and the Toyota Production System, which regulate management practices), which directly influences micro-operations (Bhattacharya, 2014).

Thus, the company avoids utilising long assembly lines, the use of rounded-off sets of tasks is supported, and the overall assembly line is divided into several specific segments with a separate quality control for each segment (Bhattacharya, 2014; Gao & Low, 2014). From this perspective, managers are interested in developing a continuous flow of processes that are based on the Lean Systems approach to address the issues of overproduction and quality (Gao & Low, 2014). These approaches allow for increasing the quality of produced parts or components and minimising the resources used.

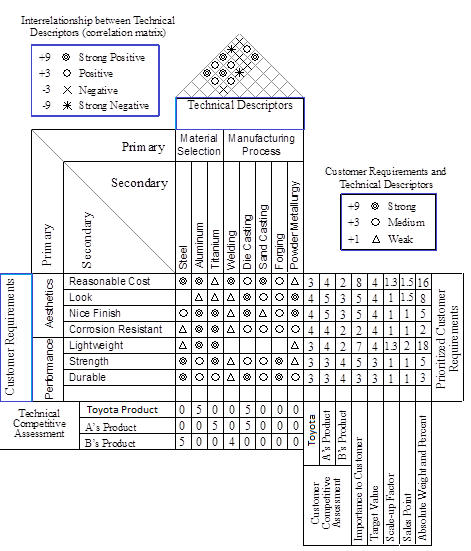

The House of Quality is a specific technique in operations management that includes taking customers’ preferences into account while developing and manufacturing a product. This approach has been actively used in Toyota since the 1970s, when this method was developed and adopted by Japanese manufacturers of automobiles, equipment, and electronics (Barnes, 2017). The focus is on determining customers’ preferences regarding the expected design and qualities of a specific product with reference to certain target values (Barnes, 2017; Bhattacharya, 2014). This approach is important for Quality Function Deployment and quality planning in order to design an effective product that will address customers’ expectations.

The following components comprise the House of Quality: customers’ requirements and expectations regarding a product, prioritised customer requirements, an importance rating provided by customers, benchmarking, target values, and technical descriptors.

Thus, the matrix includes the sides or walls, the ceiling, the roof, and the floors, which are composed of these parts. The interior parts of the house represent the relationships that are observed between customers’ specific requirements and certain technical descriptors that have been determined for a product (Bhattacharya, 2014; Barnes, 2017). In addition, the house has a roof, representing the interrelationship between the technical descriptors that have been identified.

The example of Toyota presents an opportunity to analyse the application of this technique to choosing materials and design aspects for the X components of the body of some of Toyota’s vehicles. The analysis will be conducted with reference to a comparison of Toyota’s products to the products manufactured by two of its competitors, companies A and B. Figure 1 represents the House of Quality matrix that was developed to address this task.

The major customer requirements regarding the car body are its aesthetics and performance qualities. These requirements are subdivided into look, cost, finish, resistance to corrosion, light weight, durability, and strength. In the section for technical descriptors, the materials to be used and the specifics of the manufacturing process are listed. With reference to certain aspects, customer requirements and technical descriptors seem to be highly correlated, for example, cost and steel, cost and aluminium, and strength and steel, among others. The analysis of the House of Quality makes it possible to reach a decision regarding the design and development of the X component that addresses both technical issues and customers’ preferences.

Toyota Competitive Capabilities

A company’s general competitive capabilities include its situation regarding product prices and production costs to make a manufacturing process cost-efficient, the quality issue, the speed of product delivery, dependability, its focus on innovation and flexibility, productivity, and sustainability (Barnes, 2017). Toyota’s competitive advantage is also based on these capabilities, which need to be discussed in detail.

The cost structure in Toyota is very effectively organised because of its close relationships with suppliers (Toyota USA, 2019). Furthermore, well-organised production processes and good distribution channels allow the company to control costs (Barnes, 2017; Bhattacharya, 2014). Still, these processes do not contribute to decreasing prices to attract more customers: cost-efficient production is used in the company along with a distinctive price policy to accentuate the reputation and quality of the company’s vehicles.

Toyota is able to produce high-quality cars through its specific Toyota Production System and an associated philosophy based on the principles of lean manufacturing. As a result of applying these rules, the company has improved its manufacturing process, interaction with suppliers, logistics, and quality control processes (Toyota USA, 2019). All these principles and rules are known as the Toyota Way, and they allow for manufacturing cost-efficient but high-quality products that are attractive to customers because of their design, innovation, and safety (Bhattacharya, 2014; Gao & Low, 2014).

In addition, attention is given to the organised delivery of products through official dealers and distributors in different regions of the world. Thus, capabilities related to speed and dependability are also addressed.

The company’s productivity is also based on the Toyota Production System and the Kaizen philosophy. It is important to note that, in the context of Toyota, the Kaizen philosophy means a focus on the continuous improvement of all operations and functions in the organisation in order to increase productivity through involving all employees in the process (Bhattacharya, 2014; Gao & Low, 2014). Just-in-time is one more concept utilised by Toyota in order to improve its operations through optimising all actions and processes while avoiding repetitive or unnecessary steps and activities (Bhattacharya, 2014).

Furthermore, s ustainability is one of the key principles on which Toyota’s philosophy is based. The company pays close attention to balancing the use of economic, human, and environmental resources. The major action in this context is the production of hybrid and electric cars. In addition, the company is developing and improving its waste management and recycling systems ( Toyota, 2018; Toyota USA, 2019). It is also focused on decreasing the use of water and energy resources in its operations.

Toyota Vs. Nissan Competitive Capabilities

A polar or radar chart can illustrate the comparison of two organisations from one sector with respect to certain performance objectives while using a scoring system to determine the importance these organisations assign to various performance indicators. By comparing the strategies followed by Toyota and Nissan in this area, it becomes clear that Toyota pays maximum attention to and spends considerable resources on achieving high-level quality and the degree of flexibility associated with innovation (Figure 2; Barnes, 2017).

For Nissan, the aspect of quality is also the key priority (Nissan, 2019). Sustainability and productivity are also critical performance objectives and competitive capabilities for Toyota that guarantee its competitive advantage.

In the case of Nissan, the other priority is cost in order to preserve its price leadership in the market. Cost and delivery issues are not viewed by Toyota’s managers as requiring additional attention because these areas are effectively regulated by the company’s policies ( Toyota, 2018 ). When comparing the situation of Toyota with Nissan’s capabilities, it is important to note that flexibility and sustainability are lower priorities for Nissan, and speed and dependability receive almost the same scores.

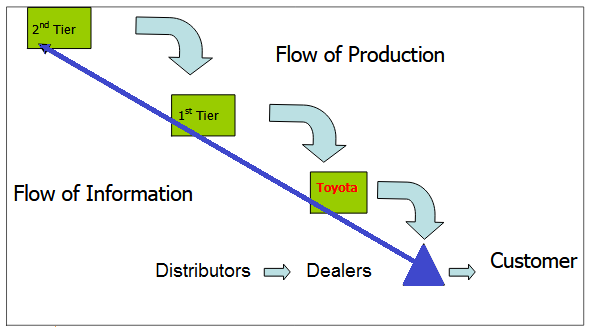

Toyota Supply Chain & Recommendations

The supply chain of Toyota involves suppliers of the first and second tiers that initially competed against each other in order to cooperate with the company. In this context, first tier suppliers provide Toyota with particular systems that are not interchangeable, and second tier suppliers produce certain parts or components of these systems (Kito, Brintrup, New, & Reed-Tsochas, 2014).

According to the Toyota Production System, the focus is on those suppliers that can decrease the costs of production but that use the most innovative and high-quality technologies (Bhattacharya, 2014). Furthermore, the supply chain system currently in use is based on the just-in-time principle, and the need for certain components and parts is addressed only when this need is observed because the connection with suppliers is well organised.

First tier suppliers actively participate in the process of product development, and they receive the order after presenting and testing the prototype or model of a certain system for Toyota. The company leaders make decisions after analysing performance and costs related to the prototype. In the context of the Toyota Production System and lean manufacturing to decrease costs and the overuse of resources, suppliers are encouraged to communicate with each other and develop the most cost-efficient solutions (Bhattacharya, 2014).

Second tier suppliers produce parts and provide components depending on the needs of first tier suppliers. As a result, specific functional units are organised. First tier suppliers are viewed as responsible for product design and engineering, while second tier suppliers are responsible for micro-operations and process engineering (Kito et al., 2014). From this perspective, relationships between suppliers are developed, employees actively communicate and cooperate, and decisions are made and problems are resolved in pursuit of key objectives and by involving first tier and second tier employees. Figure 3 illustrates the supply chain of Toyota with a focus on flows of information and production between customers, the company, and suppliers.

Although this supply chain is effective and characterised by highly positive outcomes, there are challenges associated with supply chain management. The problem is that all suppliers working with Toyota are expected to be actively involved in the company’s operations and share knowledge and resources while being guided by the principles of the Toyota Production System. Therefore, some improvements can be made in order to contribute to more effective supply chain management for the company.

Firstly, more attention should be paid to implementing and improving technologies for sharing secured corporate data. Secondly, more attention should be paid to organising training for new suppliers about working in the context of the Toyota Production System and the Toyota Way philosophy (Gao & Low, 2014). The active integration of suppliers into the activities and culture of Toyota requires additional training so that they can achieve better results through collaboration.

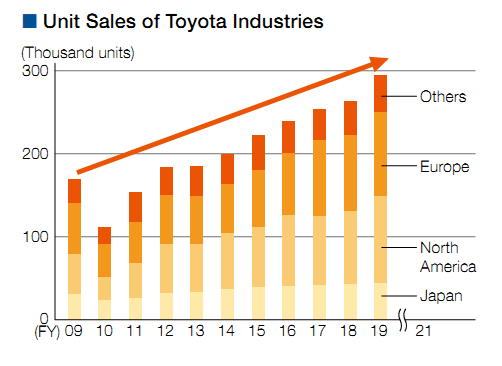

Forecasting future demand is important for operations management in order to determine what capacity should be guaranteed from a long-term perspective. Depending on the products and services companies sell, they can choose between different forecasting methods, including focusing on the average and exponential smoothing (Bhattacharya, 2014; Barnes, 2017). Toyota makes use of various forecasting techniques depending on trends in customers’ behaviour in order to plan capacity and production processes (Ludwig, 2015). Regional dealers provide monthly reports, including data on forecasting for the next three months, as well as contacting distribution centres to discuss the demand.

Toyota uses specific demand forecasting software to control inventory management and set the objectives for operations management. The updated version of this software allows for including more factors that can influence increases and decreases in demand. Thousands of forecasts are analysed with the help of this software monthly (Ludwig, 2015). With reference to the forecasts and analysis provided in the Toyota Industries Report for 2018, it is possible to predict further increases in demand for products in Japan, the United States, Europe, and other regions (Toyota, 2018). The numbers of units forecast to be sold are presented in Figure 4.

In the automotive industry of Japan and globally, Toyota takes a leading position while being associated with such features and characteristics as innovation, safety, durability, and flexibility in products and operations.

This report has presented an analysis of Toyota’s micro-operations, a House of Quality analysis based on customers’ expectations regarding one of the company’s products, the competitive capabilities of the company, and its prioritisation and realisation of performance objectives. In addition, the report has also provided a discussion of the company’s supply chain and the application of a forecasting technique to the case of Toyota.

It should be stated that the company’s reputation and popularity among customers depend on its high-quality and highly innovative products. Still, it is also important to note that the exceptional success of the company’s operations management depends on the Toyota Production System and the company’s specific philosophy, which allow it to increase productivity and quality, contribute to cooperation between suppliers, reduce costs, focus on innovation, and achieve sustainability. From this perspective, the operations management strategies and methods that are applied by Toyota appear to contribute to its continued strength and growth in the industry.

Barnes, D. (2017). Operations management: An international perspective . London, UK: Macmillan International Higher Education.

Bhattacharya, S. (2014). Operations management . Sonepat, India: PHI Learning.

Gao, S., & Low, S. P. (2014). The Toyota Way model: An alternative framework for lean construction. Total Quality Management & Business Excellence , 25 (5-6), 664-682.

Kito, T., Brintrup, A., New, S., & Reed-Tsochas, F. (2014). The structure of the Toyota supply network: An empirical analysis . Web.

Ludwig, C. (2015). Toyota part 4: Looking for the ‘holy grail’ of predictability . Web.

Nissan. (2019). Our company . Web.

Toyota. (2018). Toyota industries report 2018 . Web.

Toyota USA. (2019). Our story . Web.

Cite this paper

Select style

- Chicago (A-D)

- Chicago (N-B)

BusinessEssay. (2023, January 10). Toyota Operations Management & Demand Forecasting. https://business-essay.com/toyota-company-operations-and-supply-chain-management/

"Toyota Operations Management & Demand Forecasting." BusinessEssay , 10 Jan. 2023, business-essay.com/toyota-company-operations-and-supply-chain-management/.

BusinessEssay . (2023) 'Toyota Operations Management & Demand Forecasting'. 10 January.

BusinessEssay . 2023. "Toyota Operations Management & Demand Forecasting." January 10, 2023. https://business-essay.com/toyota-company-operations-and-supply-chain-management/.

1. BusinessEssay . "Toyota Operations Management & Demand Forecasting." January 10, 2023. https://business-essay.com/toyota-company-operations-and-supply-chain-management/.

Bibliography

BusinessEssay . "Toyota Operations Management & Demand Forecasting." January 10, 2023. https://business-essay.com/toyota-company-operations-and-supply-chain-management/.

- Zimmer Motor Company Global Strategy

- Taco Bell Brand: Strategic Plan and SWOT Analysis

- Apple Company’s Analysis

- Walmart Company’s Global Strategy and International Business

- Ryanair Company’s 7 Ps Product & Service Analysis

- Toyota Motor Organisation in Context

- Volvo and Tesla: Strategic Management Project

- Marriott International Company’s Strategic Direction

- Emirates Airlines’ Operations Management Analysis

- Abu Dhabi Oil Company’s Strategic Analysis

- Systems and Operations Management Practices at Airbus

- Airbus Company’s Operations Management and Systems

- New Age Recyclers Company’s Business Plan

- Casper & Gambini’s Company’s Strategic Analysis

- Royal Dutch Shell Corporate Governance and Ethics

Toyota Motor Corporation: Company Analysis Research Paper

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

Introduction

Toyota Motor Corporation was founded in 1937 by a gentleman called Kichiro Toyora. The company has been named as one of the most admired company dealing in cars for a myriad of years. The company made a serious mistake in 1960s after it had produced Toyopet. This was labeled as a defective car which was unsuited for hilly terrains in the US.

The company later came strong and has since managed to be at the heart of a myriad of Americans with various car innovations, creational of job opportunities through the process of building assembly lines in different parts of the world specifically in the US. Currently, the company has continued to top the truck (Tacoma), sedan (Camry), mid range vehicle (Camry) and Van (Sienna) markets.. (Fujimoto 1999)

The company has the largest share in the global auto mobile industry due to its high outstanding financial records, market, areas of opportunity and finally data. In 2010, the company employed 300,734 people across the world and it was ranked as second in the automobile production in 2010 in terms of production.

By 2012, Toyota reported that it had manufactured almost 200 Million vehicles. Toyota is currently traded in Osaka, Fukuoka, Sapporo and Tokyo. The company is foreign listed in the London and New York Stock Exchange. (Fujimoto 1999)

Strategy (or combination of strategies) used by Toyota to turn it into a powerhouse

The company was able to change its image in 60s and 70s attracting million of customers across the world. The company went greatest upgrade when they introduced the kaizen principle. This was a philosophy which saw increased improvements in the company. The company is important as it’s seldom for the time and progress to remain still.

It is the largest producer in the world and has remained true to the Kaizen principle. The company also applied the two major strategies and principles which were relevant to Porter’s goals. According to Porter, the strength of the company falls into two major strategies; law costs and differentiation. (Nemoto & Lu 1987)

Going by the strength, the company can keep four other strategies; differentiation, cost leadership strategy, differentiation focus strategy and low cost strategy. The company had a marketing strategy which made it possible in the conquering of the world market though facing stiff competition from German companies such as Volkswagen. The company took the steps towards the prevention of promotion of the production of the Volkswagen in the US.

The Japanese experts conducted thorough investigations of the causes of high competitiveness of the cars from German and high to curb the competition superior than those of the competitors. The company followed the policy towards the introduction of the car to the whole world. The company made a car which was better than Volkswagen in terms of the car interior and also the price of the same.

To what extent has Toyota’s strategy (or combination of strategies) changed over the years, or been constant

Toyota Company has undergone different stages in terms of its management and strategies which are meant to ensuring that the sales of the company went high. The kaizen principle has in the past undergone different strategies which have helped it remain the top of the automobile industry across the globe. The marketing strategy which the company applied helped be one of the most lucrative companies in the industry.

The strategy was meant to attract many clients worldwide and reducing the operations of Volkswagen in the US. The continuous upsurge in the sales of the company has been as a result of different changing strategies with time. Given the divergent nature of the market, various combinations of strategies have been changing from one time to a number so as to attract many people in the economy. (Mirza 1998)

How does Toyota’s strategy (or combination of strategies) “fit” with the environment of the automobile industry?

The environment in the automobile industry has been changing from 1960s to date. The company has one a myriad of stages relating from suppliers, competition, financing among others. The first consideration is the threat f new entrants. The strategy of the company has made it easier for them to reduce the existing of new entrants and others from expanding.

The presence of less suppliers of a given product and also the absence of substitutes for the particular product supplied shows the real pressure which is exerted by the real suppliers. The strategy by the company has ensured that those suppliers which are extremely important for the successful operations of the company are availed. (Nemoto & Lu 1987)

Marketing environment in the automobile industry has been competitive. In the auto mobile industry, the major factors which are taken into consideration by clients are price and quality of the product submitted. Toyota ensured that the products they presented to the market were o f very high quality and price friendly. This has made it possible for them to i9ncrease the number of recorded sales on annual basis. (Mirza 1998)

How does Toyota’s strategy (or combination of strategies) “fit” with the internal resources and competencies of the firm?

During the 1960s the company was not operating in the economies of scale and had to use the scarce resources which are there. The strategy which is adopted by Toyota is driven towards ensuring that the revenue which the company records surpass the costs which it adopts.

The planning department works towards ensuring that the values which are presented to the cost accounting department are enough towards the production of the number of cars that helps the company remain profitable. The strategies which the company has implemented has worked t9owards ensuring that they fit with the competencies that the firm has besides taking into consideration the internal resources that it has. (Magee 2007)

Recommendations

For any company to remain profitable, it is important that it minimizes the costs as possible. This paper advances some of the below recommendations to help improve its operations;

Strategies towards reducing the costs; Toyota should ensure that the marginal revenue at any point of its operations is also equivalent to its marginal costs. This will make the company remain profitable.

Marketing should be advanced to convince the populace so as to purchase more of the company products. This will help increasing the company sales.

The company should increase its expenses on the marketing research. This will enable the company know what the customers need. From here the internal and external fittings will be in line with the requirements of the customers. This will see the increase of the company sales as the products which are manufactured will be easily demanded by customers. (Magee 2007)

Fujimoto, T. (1999). The evolution of a manufacturing system at Toyota . New York: Oxford University Press.

Magee, D. (2007). How Toyota became #1: leadership lessons from the world’s greatest car company . New York: Portfolio.

Mirza, H. (1998). Global competitive strategies in the new world economy: multilateralism, regionalization, and the transnational firm . Cheltenham, UK: Edward Elgar.

Nemoto, M., & Lu, D. J. (1987). Total quality control for management: strategies and techniques from Toyota and Toyoda Gosei . Englewood Cliffs, N.J.: Prentice Hall, Inc..

- Wal-Mart Analysis

- Company Analysis: Facebook

- Volkswagen Company's Marketing Strategy in China

- Volkswagen Company: Sales Team Management Plan

- Six Sigma Approach and Its Benefits

- Starbucks: Successful Product Promotion Program

- XYZ Motor Company Profile

- Apple Company's Present and Future

- Lenovo Company Analysis

- Walmart Company Analysis

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2019, April 16). Toyota Motor Corporation: Company Analysis. https://ivypanda.com/essays/toyota-motor-corporation-company-analysis/

"Toyota Motor Corporation: Company Analysis." IvyPanda , 16 Apr. 2019, ivypanda.com/essays/toyota-motor-corporation-company-analysis/.

IvyPanda . (2019) 'Toyota Motor Corporation: Company Analysis'. 16 April.

IvyPanda . 2019. "Toyota Motor Corporation: Company Analysis." April 16, 2019. https://ivypanda.com/essays/toyota-motor-corporation-company-analysis/.

1. IvyPanda . "Toyota Motor Corporation: Company Analysis." April 16, 2019. https://ivypanda.com/essays/toyota-motor-corporation-company-analysis/.

Bibliography

IvyPanda . "Toyota Motor Corporation: Company Analysis." April 16, 2019. https://ivypanda.com/essays/toyota-motor-corporation-company-analysis/.

IvyPanda uses cookies and similar technologies to enhance your experience, enabling functionalities such as:

- Basic site functions

- Ensuring secure, safe transactions

- Secure account login

- Remembering account, browser, and regional preferences

- Remembering privacy and security settings

- Analyzing site traffic and usage

- Personalized search, content, and recommendations

- Displaying relevant, targeted ads on and off IvyPanda

Please refer to IvyPanda's Cookies Policy and Privacy Policy for detailed information.

Certain technologies we use are essential for critical functions such as security and site integrity, account authentication, security and privacy preferences, internal site usage and maintenance data, and ensuring the site operates correctly for browsing and transactions.

Cookies and similar technologies are used to enhance your experience by:

- Remembering general and regional preferences

- Personalizing content, search, recommendations, and offers

Some functions, such as personalized recommendations, account preferences, or localization, may not work correctly without these technologies. For more details, please refer to IvyPanda's Cookies Policy .

To enable personalized advertising (such as interest-based ads), we may share your data with our marketing and advertising partners using cookies and other technologies. These partners may have their own information collected about you. Turning off the personalized advertising setting won't stop you from seeing IvyPanda ads, but it may make the ads you see less relevant or more repetitive.

Personalized advertising may be considered a "sale" or "sharing" of the information under California and other state privacy laws, and you may have the right to opt out. Turning off personalized advertising allows you to exercise your right to opt out. Learn more in IvyPanda's Cookies Policy and Privacy Policy .

Crash of an Ilyushin II-18V in Arkhangelsk

IMAGES

VIDEO

COMMENTS

Toyota Motor Corporation Essay. The Toyota Motor Corporation is one of the world's biggest and most favourable automobile manufacturers (Borowski). It is the leader in environmentally friendly and technologically advanced cars. The official start up for Toyota was in 1937, as Kiichiro Toyoda launched the Toyota Motor Company.

Toyota Motor Corporation, headquartered in Tokyo, Japan, the incumbent president, Shoichiro Toyoda. An annual output of the car is nearly 5 million, and exports account for nearly 50%.Toyota Motor Corporation in partnership with South Korea's Hyundai Motor Company. This essay was reviewed by. Dr. Oliver Johnson.

In 1957 Toyota Motor Sales, U.S.A., Inc., was established, and the following year the company released the Toyopet sedan, its first model to be marketed in the United States; it was poorly received because of its high price and lack of horsepower. The Land Cruiser, a 4 × 4 utility vehicle released in 1958, was more successful.

SWOT Analysis for Toyota. The SWOT analysis is a tool of strategic planning that involves characterizing the strengths, weaknesses opportunities and threats of the company; apart from that, the trends existing in the market are described in order to define the possible directions of development. Therefore, SWOT is devoted to a short summary of ...

Toyota Motor Corp., Largest Japanese automobile manufacturer and one of the largest automotive companies in the world.It was established in 1933 as a division of the Toyoda Automatic Loom Works, Ltd., and in 1937 it was incorporated as the Toyota Motor Co., Ltd. Toyota later established many related companies, including Toyoda Machine Works, Ltd. (1941), and Toyota Auto Body, Ltd. (1945).

As a result, Toyota has been able to grow its international market to a greater extent. More expanded market implies increasing sales thus, higher annual returns for the motor company. Contrarily, globalization has impacted negatively on the environment and on public health (CleanAir Systems, 2010).

NCES 1. TOYOTA CORPORATE OVERVIEW:Founded in 1937, Toyota Motor Corporation is a Japanese company that engages in the design, manufacture, assembly, and sale of passenger cars, minivans, commercial vehicles, and related parts and accessories primarily in Ja. an, North America, Europe, and Asia. Current brands incl.

Toyota, a popular Japanese brand, pride of Japan and renowned as fifth largest corporate listed by annual revenue of $254.7bn. as of March 31, 2017, was Initiated in 1937, it was first abstracted by Sakichi Toyoda in 1924 later his son Kiichiro Toyoda succeeded and Toyota Motor company came into existence, Toyota Motor Corporation is a Japanese ...

Vision statement. The vision of the company is "To be the most successful and respected car company in America" (Toyota Motor Corporation Corporate Website, 2011). The attainment of the vision will only be realized after the company has set appropriate internal processes that target the American market; the internal processes that the ...

Essays. Marketing. In 1933 company was founded by Kiichiro Toyoda. In 1934 department of Toyota industries manufactured first product the product called Type A engine and its first passenger car AA in 1936. Toyota bough.

Toyota Company objective. In its operation, Toyota is committed to its mission of becoming the market leader with regard to production of cars. The resultant effect is that the shareholders' returns will be enhanced. The firm appreciates that this can only be achieved if its customers are satisfied. Additionally, the firm also intends to ...

I. Introduction. Toyota holds immense significance in the automotive industry, known for innovation, reliability, and transformative impact. This article explores Toyota's rich history, tracing its origins from a textile machinery company to a global automotive powerhouse. It examines the evolution of Toyota's pioneering contributions ...