Starting Peanut Butter Manufacturing Business Plan (PDF)

The peanut butter manufacturing business is a lucrative business perfectly suited for anyone. Peanut butter forms an integral of many kitchens across the world. Go to many households and you will find peanut there. Peanut butter is heavily consumed across the world. Peanut butter is a highly nutritive product which is used as bread spread and added to food like rice, relish, smoothies, sauces, cookies and porridge. It’s high in proteins and contains low calories, thus it’s considered a healthy food. Peanut butter manufacturing is a very profitable business which can even been done at a small scale using little capital. Many entrepreneurs from all over the world are making money from peanut butter production business. This article will outline how to start the peanut butter business, and the peanut butter business plan – PDF, Word and Excel.

Peanut butter production is a lucrative business, providing income for millions of families, but there are some essential decisions that you need to make before you venture into the peanut butter business. You have to decide on the size of your peanut butter manufacturing project i.e. the amount of peanut butter that you want to produce daily; location of the peanut butter manufacturing business e.g. a peanut butter plant/factory , and your target market. These choices will be affected by the amount of capital you have, and the size and needs of your target market. If you do not have a lot of capital, you can always start small and grow your peanut butter project overtime. You also need to carry out market research (Who are you going to sell the peanut butter to? At what price?) and write a peanut butter business plan before you start the peanut butter production project.

Market Research

Look into the monopolistic competition element.

The peanut butter market is generally characterised by monopolistic competition. This means the peanut butter market is midway between absolute competition and monopoly. In such a market the product sold (peanut butter in this case) is unique but having close (but not perfect) substitutes. That is an important aspect to understand in the peanut butter market.

Thus the competition you will deal with is dual i.e. other peanut butter manufacturers and players selling substitutes. You must research to find out what the metrics are like regarding that dynamic. Another thing to look into here regards peanut butter imports. That could be a credible threat to the viability of your peanut butter manufacturing business.

Find Out Regarding Peanut Butter Customer Segments

Peanut butter is chiefly processed as either smooth or crunchy. You have to understand what is consumed most and by who i.e. consumer preferences. You can get even more information by looking into the distribution dynamics. Peanut butter is often found in supermarkets and small shops. Find out average peanut butter order quantities and sales volumes. Studying those can inform on the nature of customer segments. Knowing your target peanut butter market customer personas helps you cater to consumers’ specific needs.

Researching Peanut Butter Market Opportunities

Your peanut butter manufacturing market research is mainly concerned with identifying market opportunities. You have to find out what your key competitors are. What products and services do they offer? What marketing strategies are they employing? What is their market share? Where are they located? Where do they get their raw materials? What are their selling prices? These are some of the things to find out.

For medium to large scale peanut butter manufacturing, there is need of finding industrial premises for the peanut butter plant. The premises should have sufficient electricity supply to power all the peanut butter machines. It is advisable to locate your peanut butter plant closer to the target market so as to minimise transport costs . Other factors which may determine the location include: proximity to raw materials, availability of affordable labour and electricity. Small scale peanut butter production can even be carried from residential premises.

Permits/Licenses, Insurance & Business Bank Account

This is the food industry, getting licensed or a permit is non-negotiable. You must also properly register your peanut butter manufacturing business. Your business premises and operations need to be covered by insurance. All finances for your peanut butter manufacturing business must be managed via a separate business bank account. These 3 elements make your peanut butter manufacturing business compliant, authentic, and structured.

Machinery & Equipment for Peanut Butter Manufacturing Business

Peanut Butter is produced from peanuts/groundnuts. However, the shells of the peanuts need to be removed first. This is done using a Sheller Machine. Peanut shellers clean, shell and sort peanuts prior to further manufacturing process. A sheller is optional, as you can buy shelled peanuts/groundnuts instead of unshelled ones. The shelled groundnuts/peanuts will then have to be roasted. Roasting is a process by which heat is supplied to the groundnuts. This is done using a Roaster Machine. The roasted peanuts are then passed through a blancher machine which emoves the remaining outer skins of the peanuts that still remain after roasting.

The peanuts/groundnuts are then fed into a peanut butter grinding/milling machine. This the main machine needed for the peanut butter production business. It grinds the roasted groundnuts till smooth peanut butter is produced. After the peanut butter is produced, it will then be packed into the peanut butter jars using a peanut butter filling machine. So you need to also have peanut butter jars, which can be of different sizes to cater for different customer needs. The peanut butter jars will need to be labeled. This is usually done by self-adhesive paper which is printed and wrapped around the peanut butter jars. Your peanut butter business plan should take into account the costs of purchasing the machinery and equipment.

Raw Materials for Peanut Butter Production

The major raw material used to make peanut butter is peanuts/groundnuts. They are roasted and milled to produce peanut butter. The cost and quality of the groundnuts which you use play a significant role in determining the profitability and success of your peanut butter manufacturing business. Peanuts which are big are the ones which make good quality peanut butter. Before you start the peanut butter business, you should take into consideration the price of peanuts/groundnuts and the selling price of the peanut butter. If the groundnuts are too expensive, your business will encounter heavy losses. Our peanut butter production business plan comes with excel financial statements which will assist you in determining the profitability of the business, taking into consideration the price of the peanuts and other raw materials. Other raw materials include salt, emulsifier, stabilisers, additives, and sweeteners.

Inventory Management

The main focus is raw materials and the processed peanut butter. The main raw materials are peanuts (or groundnuts) and salt. You need to always ensure you have enough to cater for your peanut butter manufacturing needs. Machinery must also be kept in check. You must have a detailed process flow so that it is easy to know when anything needs to be replenished. The same goes for the processed peanut butter. You need to strike a balance between having in stock in line with demand for it. The ideal scenario is for it to go to market as soon as it is processed. This calls on you to get a digital inventory management system to streamline your peanut butter manufacturing operations.

Factory workers are needed to carry out the actual production of peanut butter, acquiring the raw materials, operating the machines, and packing the peanut butter. Of importance is quality control: sorting and grading groundnuts/peanuts before and after roasting, as well as checking the quality of peanut butter produced. Employees are also needed for accounting, sales, marketing, logistics, supervisory and management roles. The number of employees you need will depend on the size of your peanut butter production business. Your peanut butter making business plan should take into account the costs of purchasing the machinery and equipment.

Capital for Peanut Butter Business

The amount of capital required for the peanut butter manufacturing business depends on the scale of the project. You can get a loan from the bank, or funding from investors, to use as capital to start your peanut butter production business. If you plan to raise capital from investors and a loan from the bank, you need a good peanut butter production business plan. If you don’t have access to investors and bank loan, you can use your personal savings and start small, and grow your business overtime. Peanut Butter business is very profitable, so if you reinvest the profits you get, you can quickly grow. Even if you are not planning to get a loan, you should still get a peanut butter business plan to guide you in starting and operating the business. It is essential for you to have a peanut butter manufacturing business plan before you venture into the business, so that you know all the costs involved and you make an informed decision.

Marketing Plan

Your target markets can be wholesalers and retailers. Having your peanut butter in supermarkets and shops builds brand awareness. Thus the best marketing approach is to engage such players directly. You can also directly sell to consumers – hassle-free and more lucrative. Having an active online presence i.e. website and social media accounts is essential. Branding and using alluring signage on your premises and in strategic areas helps as well. Invest in attractive, memorable, and informational packaging for your peanut butter.

The market for peanut butter is very huge and is ever increasing. Increasing working population, rising disposable income, rising demand for nutritious products, and rapid urbanisation, have resulted in increasing demand for peanut butter. You can supply your peanut butter to supermarkets, wholesalers, tuckshops, individual households, schools, restaurants & fast food outlets, companies, organisations and events etc. For large scale production of peanut butter, you can also end up exporting it to other countries. The peanut butter production business plan ought to include a proper marketing plan to use in your peanut butter business.

Keys To Profitability

Capitalize on rising global health food awareness.

Health food (not healthy food) is natural food that is deemed to have health-giving qualities. Health foods typically comprise core nutrients namely, carbohydrates, protein, fat, vitamins, and minerals. Globally there is a growing awareness and demand for health foods. More and more people are leaning more on only eating health foods. Peanut butter is a good example of a health food. If you want to push volumes for your peanut butter manufacturing business, sell the health food benefit. Incorporate it in your branding and marketing to appeal more to consumers.

Figure Out Ways To Reduce Costs Of Sourcing Quality Groundnuts

Groundnuts are a major input in the peanut butter (over 90 percent) manufacturing business. They are mostly not easy to come by thus making them costly. No wonder most peanut butter manufacturers are inflexible on pricing their peanut butter. If you can get your hands on cheaper groundnuts, you get a competitive advantage via pricing flexibility. Search far and wide for cheaper groundnuts. Farmers who often grow them can be situated far away from urban or peri-urban areas. Their being far away usually makes them sell their groundnuts for much cheaper prices. Do your research into finding such groundnut farmers. You can even consider investing groundnut farming; it could reduce the cost of sourcing groundnuts.

Provide A Comprehensive Range Peanut Butter (Type And Size-Wise)

Customer preferences when it comes to peanut butter are varied. Some prefer smooth peanut butter, whereas some prefer crunchy peanut butter. Some even prefer newer variations such chocolate peanut butter. You need to provide what adequately serves those preferences. Closely tied to that, are the sizes of the peanut butter containers. Informed by empirical bases, package your peanut butter ranging from the smallest units to the biggest units. All in all, there must be something for everyone.

There are many underserved markets. Shortages of peanut butter are commonplace in some areas. Most peanut butter manufacturing businesses still focus on traditional approaches. These are opportunities for you to start a distinguished peanut butter manufacturing business.

Pre-Written Peanut Butter Manufacturing Business Plan (PDF, Word And Excel): Comprehensive Version, Short Funding/Bank Loan Version and Automated Financial Statements

For an in-depth analysis of the peanut butter production business, we encourage you to purchase our well-researched and comprehensive peanut butter manufacturing business plan. We introduced the business plans after discovering that many were venturing into the peanut butter making business without enough knowledge and understanding of how to run the business, lack of understanding of the financial side of the business, lack of understanding of : the industry, the risks involved , costs and profitability of the business; which often leads to disastrous losses.

The StartupBiz Global peanut butter manufacturing business plan will make it easier for you to launch and run your peanut butter production business successfully, fully knowing what you are going into, and what’s needed to succeed in the business. It will be easier to plan and budget as you will be aware of all the costs involved in setting up and running the peanut butter business.

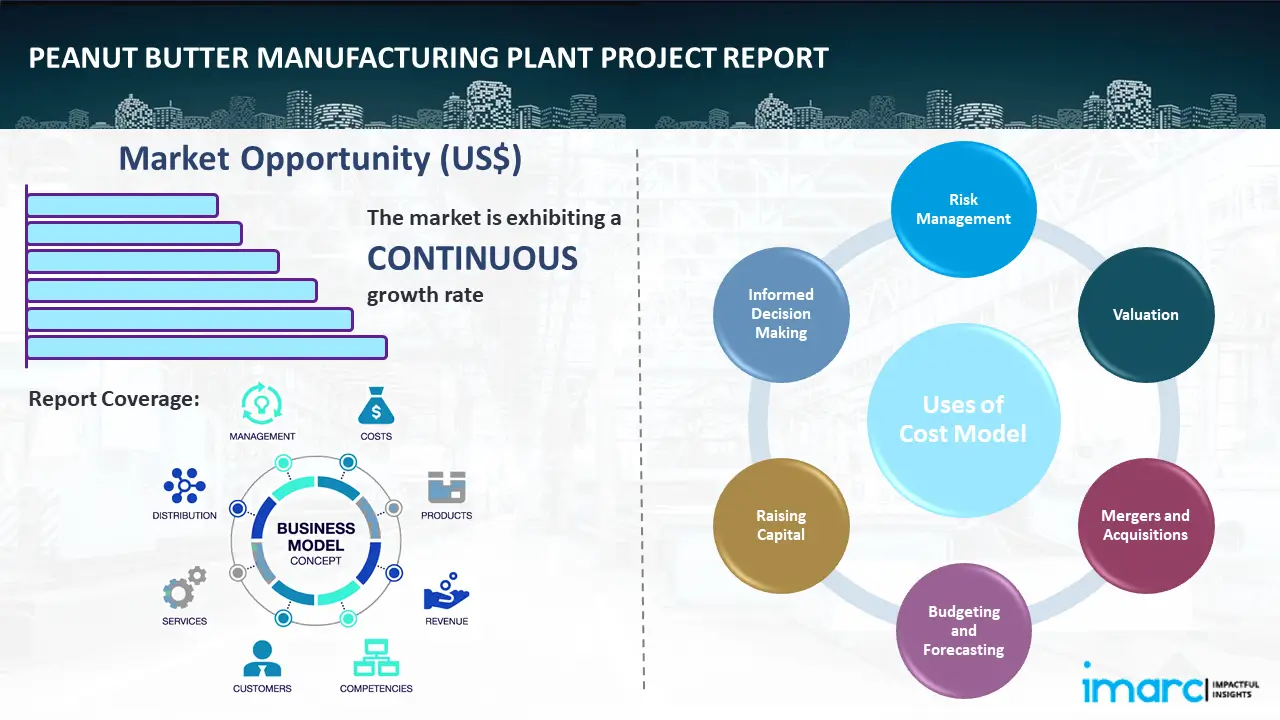

Uses of the Peanut Butter Business Plan (PDF, Word And Excel)

The peanut butter business plan can be used for many purposes including:

- Raising capital from investors/friends/relatives

- Applying for a bank loan

- Start-up guide to launch your peanut butter manufacturing business

- As a peanut butter production business proposal

- Assessing profitability of the peanut butter manufacturing business

- Finding a business partner

- Assessing the initial start-up costs so that you know how much to save

- Manual for current business owners to help in business and strategy formulation

Contents of the Peanut Butter Production Business Plan (PDF, Word And Excel)

The peanut butter business plan include, but not limited to:

- Marketing Strategy

- Financial Statements (monthly cash flow projections, income statements, cash flow statements, balance sheets, break even analysis, payback period analysis, start-up costs, financial graphs, revenue and expenses, Bank Loan Amortization)

- Risk Analysis

- Industry Analysis

- Market Analysis

- SWOT & PEST Analysis

- Operational Requirements

- Operational Strategy

- Why some people in the peanut butter business fail, so that you can avoid their mistakes

- Ways to raise capital to start your peanut butter manufacturing business

The Pre-written peanut butter business plan package consists of 4 files

- Peanut Butter Manufacturing Business Plan – PDF file (Comprehensive Version – 77 Pages)

- Peanut Butter Manufacturing Business Plan – Editable Word File (Comprehensive Version – 77 Pages)

- Peanut Butter Manufacturing Business Plan Funding/Bank Loan Version- Editable Word File (Short version for applying for a loan/funding – 44 pages)

- Peanut Butter Manufacturing Business Plan Automated Financial Statements – (Editable Excel File)

The business plan can be used in any country and can be easily edited. The financial statements are automated. This implies that you can change eg the amount of peanut butter produced per day, selling price of the peanut butter etc, and all the other financial statements will automatically adjust to reflect the change.

Click below to download the Contents Page of the Peanut Butter Manufacturing Business Plan (PDF)

Testimonial 4

The business plan which I purchased from your website saved me TIME and MONEY! The layout of the business plan was excellent. The financial statements were detailed and easy for me to edit. I will come back to purchase another business plan soon.

Testimonial 5

I was able to understand the business side of farming because of your business plan. You did extensive research; the business plan was well prepared and fully detailed. It made everything clear, and I have somewhere to start now. I am confident that I am going to succeed in my business because of the guidance from your business plan.

Testimonial 7

I found Startupbiz Global online when I was in desperate need of a business plan. I was overwhelmed by the quality of the business plan, it’s comprehensive and well researched! I did not have to wait to get the business plan, I got it instantly after payment. I highly recommend Startupbiz Global, and would happily use them again in the future.

Testimonial 1

StartupBiz Global provided a very professional and comprehensive business plan which I used for my business. The business plan was easy to edit, and I was able to get the funding which I wanted. I highly recommend their business plans.

Testimonial 8

Just wanted to say I am very happy with the business plan and I will gladly recommend your products, thank you very much and have a great day.

Testimonial 6

I purchased a business plan from you, and I’m glad to inform you that I was able to get my loan, and I’m starting my poultry farming business on the 1 st of July. This was made possible because of your business plan. Thank you very much, you made my dream come true.

Testimonial 2

Many thanks for your incredibly efficient service and thorough business plan. I am very impressed with the business plan. Before I bought the business plan, I tried to do my own business plan – it was such a nightmare and it turned out badly, also not to mention the stress it caused me. I wish I knew about your website earlier!

Testimonial 3

I was extremely lucky to come across StartupBiz Global. Their business plan exceeded my expectations, and most importantly I was able to secure a loan from my bank. Thank you guys, now my dreams are coming true!

Get the Peanut Butter Manufacturing Business Plan (PDF, Word And Excel)

Click Buy Now below to purchase using Paypal, Credit Card, or Debit Card. After you have purchased, you will immediately see the download link for the business plan package on the screen. You will also immediately get an email with the business plan download link. The Pre-written business plan package (PDF, Word, and Excel) costs $30 only!

If you want to purchase multiple business plans at once then click here: Business Plans Store.

The business plan package is a zipped compressed file containing the PDF, Word and Excel documents. To open the package after downloading it, just right click, and select Extract All. If you have any problems in downloading and opening the files, email us on [email protected] and we will assist you.

We wish you the best in your peanut butter manufacturing business! Check out our collection of business plans , and more business ideas .

Related Posts

Top 10 Profitable Woodworking Projects To Build And Sell

Starting a Profitable 3D Printing Business

Starting an Internet Cafe Business Plan (PDF)

Top 11 Profitable Transport Business Ideas

Peanut Butter Making Business Plan [Sample Template]

By: Author Solomon O'Chucks

Home » Business Plans » Food Sector

A peanut butter making business is a type of food manufacturing venture that specializes in producing and selling peanut butter products.

Peanut butter is a popular spread made from roasted peanuts that are ground into a smooth or chunky paste, typically mixed with other ingredients like sugar, salt, and vegetable oils.

Suggested for You

- Food Testing Lab Business Plan [Sample Template]

- Soft Serve Ice Cream Business Plan [Sample Template]

- Chocolatier Business Plan [Sample Template]

- Beer Garden Business Plan [Sample Template]

- Deli Business Plan [Sample Template]

In a peanut butter making business, the primary focus is on sourcing high-quality peanuts, processing them into a smooth or chunky consistency, and packaging the finished product for distribution and sale.

The business may offer various flavors or variations of peanut butter, such as natural, organic, sugar-free, or flavored varieties.

Like any business, factors such as market research, competition analysis, pricing strategy, and financial planning should be considered when starting and operating a peanut butter making business.

Steps on How to Write a Peanut Butter Making Business Plan

Executive summary.

Flora Shawn® Peanut Butter Company, Inc. is a start-up food manufacturing business located in Evansville, Indiana. Our company specializes in producing and distributing high-quality peanut butter products to meet the growing demand.

We aim to become a leading brand in the peanut butter industry by offering unique flavors, superior taste, and exceptional customer satisfaction. Flora Shawn® Peanut Butter Company, Inc. is poised to disrupt the peanut butter market in Evansville, Indiana, and beyond by offering unique flavors, superior quality, and a customer-centric approach.

With our innovative product range and targeted marketing efforts, we are confident in our ability to establish a strong presence and achieve long-term success in the industry. Flora Shawn is the founder and CEO of Flora Shawn® Peanut Butter Company, Inc.

Company Profile

A. our products and services.

Flora Shawn® Peanut Butter Company, Inc. offers an extensive range of flavors, catering to diverse palates and preferences. From classic smooth and crunchy varieties to unique combinations like honey-cinnamon and dark chocolate swirl, we provide options that excite the taste buds.

Our peanut butter products are crafted to offer nutritional value, with options that are low in sugar, free from additives, and suitable for various dietary needs.

b. Nature of the Business

Our peanut butter making company will operate both the business-to-consumer business model and the business-to-business model.

c. The Industry

Flora Shawn® Peanut Butter Company, Inc. will operate in the food manufacturing industry.

d. Mission Statement

At Flora Shawn® Peanut Butter Company, Inc., our mission is to create exceptional peanut butter products that nourish and delight our customers. We are committed to crafting premium-quality peanut butter using the finest ingredients, innovative flavors, and sustainable practices.

e. Vision Statement

At Flora Shawn® Peanut Butter Company, Inc., our vision is to delight consumers with premium peanut butter products that elevate their snacking and culinary experiences. We strive to be recognized as a trusted brand known for our commitment to quality, innovation, and customer-centricity.

f. Our Tagline (Slogan)

Flora Shawn® Peanut Butter Company, Inc. – “Peanut Butter Perfection!”

g. Legal Structure of the Business (LLC, C Corp, S Corp, LLP)

Flora Shawn® Peanut Butter Company, Inc. will be formed as a Limited Liability Company (LLC).

h. Our Organizational Structure

- Chief Executive Officer (Owner)

- Quality Control Staff

- Administrative Assistant (Cashier)

- Production Staff

- Logistics and Shipping Staff

- Customer Service Executive.

i. Ownership/Shareholder Structure and Board Members

- Flora Shawn (Owner and Chairman/Chief Executive Officer) 52 Percent Shares

- Edna Paul (Board Member) 18 Percent Shares

- Klint Williams (Board Member) 10 Percent Shares

- Wisdom Martins (Board Member) 10 Percent Shares

- Kate White (Board Member and Secretary) 10 Percent Shares.

SWOT Analysis

A. strength.

- Flora Shawn® Peanut Butter Company, Inc. prides itself on producing peanut butter of exceptional quality, using the finest ingredients and rigorous quality control measures.

- The company offers a diverse range of innovative flavors, setting it apart from competitors and appealing to customers seeking unique taste experiences.

- By partnering with local peanut farms and suppliers, Flora Shawn® Peanut Butter Company, Inc. ensures freshness, supports the local economy, and enhances the traceability of ingredients.

- The company places a strong emphasis on customer satisfaction, providing personalized service, prompt responses, and actively seeking feedback to continually improve its products.

b. Weakness

- As a start-up, Flora Shawn® Peanut Butter Company, Inc. may face challenges in establishing a significant market presence and brand recognition compared to more established competitors.

- Building an efficient and widespread distribution network may be a challenge initially, particularly in reaching retail outlets and securing shelf space in competitive markets.

c. Opportunities

- The increasing trend toward healthy eating and plant-based diets presents a significant opportunity for Flora Shawn® Peanut Butter Company, Inc. to cater to health-conscious consumers seeking nutritious and flavorful alternatives.

- The company can explore expanding its market reach beyond its current location, targeting neighboring cities and regions to tap into new customer bases and increase sales.

- Leveraging e-commerce platforms and online marketing strategies can help Flora Shawn® Peanut Butter Company, Inc. reach a wider audience and increase sales through direct-to-consumer online sales.

i. How Big is the Industry?

The U.S. peanut butter market is estimated to be valued at around USD 2 billion. It is worth noting that the market is also influenced by factors such as consumer preferences, regional tastes, and health-conscious trends.

ii. Is the Industry Growing or Declining?

The global peanut butter market has been experiencing steady growth in recent years. According to market research, the global peanut butter market was valued at approximately USD 3.1 billion in 2020 and is projected to reach USD 4.2 billion by 2026, growing at a compound annual growth rate (CAGR) of around 5.2% during the forecast period. This indicates a substantial market size and potential for the peanut butter industry.

iii. What are the Future Trends in the Industry?

The peanut butter making industry is witnessing several notable trends that are shaping its future. These trends reflect evolving consumer preferences, technological advancements, and sustainability considerations.

The growth of e-commerce and the shift towards online shopping have opened up opportunities for peanut butter manufacturers to reach consumers directly. Companies are establishing online platforms, leveraging social media marketing, and offering convenient online purchasing options to cater to the increasing demand for direct-to-consumer sales.

iv. Are There Existing Niches in the Industry?

No, there are no existing niches when it comes to the peanut butter making business because the peanut butter making business is a niche idea in the food manufacturing industry.

v. Can You Sell a Franchise of Your Business in the Future?

Flora Shawn® Peanut Butter Company, Inc. will not sell franchises, but we will expand our distribution network across the United States and other parts of the world.

- The peanut butter market is highly competitive, with both established brands and new entrants vying for market share. Flora Shawn® Peanut Butter Company, Inc. needs to differentiate itself effectively to stand out in the crowded marketplace.

- Fluctuations in the cost of peanuts and other ingredients could impact the company’s profitability and pricing strategies.

- Shifting consumer preferences and emerging food trends could pose a threat if Flora Shawn® Peanut Butter Company, Inc. fails to adapt and meet evolving customer demands.

i. Who are the Major Competitors?

- The J.M. Smucker Company

- Kraft Heinz Company

- Hormel Foods Corporation

- Skippy Peanut Butter (Hormel subsidiary)

- Justin’s, LLC

- Once Again Nut Butter

- Peanut Butter & Co.

- Santa Cruz Organic

- Crazy Richard’s Peanut Butter

- Wild Friends Foods

- Georgia Grinders

- Krema Nut Company

- Woodstock Foods

- Laura Scudder’s Nut Butters

- Saratoga Peanut Butter Company

- Teddie Natural Peanut Butter

- Barney Butter

- East Wind Nut Butters.

ii. Is There a Franchise for Peanut Butter Making Business?

No, there are no franchise opportunities for the peanut butter making business.

iii. Are There Policies, Regulations, or Zoning Laws Affecting Peanut butter making Businesses?

Yes, there are policies, regulations, and zoning laws that can affect peanut butter making businesses in the United States. These regulations ensure food safety, labeling requirements, and compliance with relevant standards.

Peanut butter making businesses must comply with food safety regulations enforced by the U.S. Food and Drug Administration (FDA). These regulations include Good Manufacturing Practices (GMPs) to ensure proper handling, processing, packaging, and storage of peanut butter products.

Businesses may need to implement Hazard Analysis and Critical Control Points (HACCP) systems to identify and control potential food safety hazards.

Peanut butter products must adhere to labeling regulations set by the FDA. The labels should provide accurate and clear information about the ingredients, nutrition facts, allergen warnings, and any other required information. Compliance with specific labeling requirements, such as those related to organic or gluten-free claims, may also be necessary.

The use of specific ingredients in peanut butter products may be regulated. For example, if the product claims to be organic, it must meet the standards defined by the National Organic Program (NOP). Additionally, certain additives, preservatives, or allergens may have restrictions or specific labeling requirements.

Marketing Plan

A. who is your target audience.

i. Age Range

Our target audience includes individuals across a wide age range, particularly focusing on adults and young adults who have a strong influence on their household purchasing decisions. This typically encompasses individuals aged 18 to 45 years old.

ii. Level of Education: Flora Shawn® Peanut Butter Company, Inc. aims to reach individuals across various educational backgrounds.

iii. Income Level: Our target audience comprises individuals from various income levels.

iv. Ethnicity: Flora Shawn® Peanut Butter Company, Inc. aims to cater to a diverse range of ethnicities and cultural backgrounds.

v. Language

We primarily communicate with our target audience in English, as it is the predominant language in the regions where we operate.

vi. Geographical Location

Initially based in Evansville, Indiana, Flora Shawn® Peanut Butter Company, Inc. targets customers primarily within the local and regional markets. As we expand, we aim to reach customers across the United States, focusing on areas with a higher concentration of health-conscious individuals and those with a penchant for unique food products.

vii. Lifestyle

Our target audience consists of health-conscious individuals who prioritize high-quality, nutritious food options. They seek products that align with their active and mindful lifestyles, including those following dietary preferences such as vegan, vegetarian, or gluten-free.

b. Advertising and Promotion Strategies

- Build Relationships with players in the retail and groceries industry.

- Deliberately Brand All Our Vans and Delivery Bikes.

- Develop Your Business Directory Profiles

- Tap Into Text Marketing

- Make Use of Bill Boards.

- Share Your Events in Local Groups and Pages.

- Turn Your Social Media Channels into a Resource

i. Traditional Marketing Strategies

- Marketing through Direct Mail.

- Print Media Marketing – Newspapers & Magazines.

- Broadcast Marketing -Television & Radio Channels.

- Out-of-Home” marketing (OOH marketing) – Public Transits like Buses and Trains, Billboards, Street shows, and Cabs.

- Leverage direct sales, direct mail (postcards, brochures, letters, fliers), tradeshows, print advertising (magazines, newspapers, coupon books, billboards), referral (also known as word-of-mouth marketing), radio, and television.

ii. Digital Marketing Strategies

- Social Media Marketing Platforms.

- Influencer Marketing.

- Email Marketing.

- Content Marketing.

- Search Engine Optimization (SEO) Marketing.

- Affiliate Marketing

- Mobile Marketing.

iii. Social Media Marketing Plan

- Start using chatbots.

- Create a personalized experience for our customers.

- Create an efficient content marketing strategy.

- Create a community for our target market and potential target market.

- Gear up our profiles with a diverse content strategy.

- Use brand advocates.

- Create profiles on relevant social media channels.

- Run cross-channel campaigns.

c. Pricing Strategy

When working out our pricing strategy, Flora Shawn® Peanut Butter Company, Inc. will make sure it covers profits, insurance, premium, license, and economy or value and full package. In all our pricing strategy will reflect;

- Penetration Pricing

- Cost-Based Pricing

- Value-Based Pricing

- Competition-Based Pricing.

Sales and Distribution Plan

A. sales channels.

To effectively reach our target market, we will employ a multi-faceted marketing strategy. This will include a strong online presence through our website and social media channels, participation in local food events and farmers’ markets, and direct engagement with potential customers through tastings and demonstrations. We will also establish partnerships with grocery stores to secure consistent sales channels.

Evansville, Indiana, with its vibrant and growing population, presents a significant market opportunity for Flora Shawn® Peanut Butter Company, Inc. to establish itself as a trusted supplier of premium peanut butter.

b. Inventory Strategy

Flora Shawn® Peanut Butter Company, Inc. will implement a robust demand forecasting system to accurately predict customer demand. This can be achieved by analyzing historical sales data, market trends, and customer feedback, and considering seasonal fluctuations in demand.

We will adopt a Just-in-Time (JIT) Approach to inventory management to minimize inventory carrying costs and optimize cash flow. This strategy involves ordering and receiving inventory from suppliers as close as possible to the time of customer demand.

We will develop strong relationships with suppliers to ensure a reliable and consistent supply of high-quality peanuts. Regularly evaluate supplier performance, negotiate favorable terms, and explore opportunities for strategic partnerships to enhance supply chain efficiency.

c. Payment Options for Customers

- Bank Transfers

- Credit or Debit Card

- Electronic Payment Systems such as PayPal or Venmo

d. Return Policy, Incentives, and Guarantees

At Flora Shawn® Peanut Butter Company, Inc., our customers are our top priority hence if you receive peanut butter that is different from your receipt, we will sincerely apologize and receive the product back. But the peanut butter must be unopened, unused, and in its original packaging for a return or exchange to be eligible.

We will implement a loyalty program where customers earn points for their purchases, which can be redeemed for discounts or free products in the future. We will also offer special discounts or bundle deals where customers can purchase multiple peanut butter at a reduced price.

We will provide a satisfaction guarantee that assures customers that if they are not satisfied with the product’s taste, they can receive a refund or exchange. We will also assure customers of the high quality and effectiveness of our peanut butter by offering a guarantee against any defects or performance issues.

e. Customer Support Strategy

Customer support is a crucial aspect of any business. Hence we will make sure we provide multiple channels for customers to reach out and seek support. This will include a dedicated customer support phone line, email address, and online chat option on the company’s website. We will ensure that these channels are easily accessible and prominently displayed.

We will create a detailed Frequently Asked Questions (FAQ) section on the company’s website that addresses common customer queries. This can help customers find answers to their questions quickly and reduce the need for direct support.

We will regularly evaluate and analyze customer support metrics, such as response times, customer satisfaction scores, and complaint resolution rates. Identify areas that require improvement and implement strategies to enhance the overall customer support experience.

Operational Plan

Our operational plan will cover the day-to-day operations of the business, including production, packaging, distribution, staffing, and customer service.

a. What Happens During a Typical Day at a Peanut Butter Making Business?

A typical day at a peanut butter making business involves a combination of processing, production, quality control, sales, marketing, and administrative activities to ensure the production, distribution, and customer satisfaction with peanut butter.

b. Production Process

Here are some key aspects of a peanut butter making business:

Peanut Sourcing

Acquiring high-quality peanuts is crucial for producing good peanut butter. Peanuts can be sourced from local farms or through suppliers specializing in peanut products.

Manufacturing Process

The peanuts are typically roasted to enhance flavor and then ground into a paste using industrial grinders or mills. Additional ingredients like sugar, salt, and oils may be added during the grinding process to achieve the desired taste and texture.

The finished peanut butter is packaged into jars, bottles, or other containers suitable for retail sale. Labels with branding and nutritional information are added to the packaging.

Quality Control and Regulations

Ensuring consistent quality and adhering to food safety regulations is crucial in the food manufacturing industry. Implementing strict quality control measures and obtaining necessary licenses and certifications are important for maintaining consumer trust and complying with legal requirements.

Distribution and Sales

Peanut butter products can be distributed through various channels, including grocery stores, supermarkets, online platforms, or direct sales to wholesalers or retailers. The business may also consider participating in local markets, food festivals, or trade shows to promote its products.

c. Service Procedure

Our service procedure involves processing incoming orders, responding to customer inquiries, providing product information, and ensuring timely and accurate delivery of products.

d. The Supply Chain

The supply chain begins with the cultivation and harvesting of peanuts. This may involve partnerships with local peanut farmers, who employ sustainable farming practices to ensure the long-term viability of this marine resource.

Finished peanut butter is distributed to customers through a network of distribution channels. This may involve direct sales to retailers, partnerships with distributors, or online sales through e-commerce platforms. Orders are processed, picked, packed, and shipped to customers in a timely manner to meet demand.

e. Sources of Income

Flora Shawn® Peanut Butter Company, Inc. will make money from selling a comprehensive range of peanut butter.

Financial Plan

A. amount needed to start your peanut butter making company.

Flora Shawn® Peanut Butter Company, Inc. would need an estimate of $250,000 successfully set up our peanut butter making manufacturing company in the United States of America. Please note that this amount includes the salaries of all our staff for the first month of operation.

b. What are the Costs Involved?

- Business Registration Fees – $750.

- Legal expenses for obtaining licenses and permits – $1,300.

- Marketing, Branding, and Promotions – $3,000.

- Business Consultant Fee – $2,500.

- Insurance – $2,400.

- Rent/Lease – $85,000.

- Other start-up expenses including commercial satellite TV subscriptions, stationery ($500), and phone and utility deposits ($1,800).

- Operational Cost (salaries of employees, payments of bills et al) – $80,000

- Start-up Inventory – $25,000

- Store Equipment (cash register, security, ventilation, signage) – $1,750

- Equipment and trucks – $85,500

- Website: $600

- Opening party: $5,000

- Miscellaneous: $5,000

c. Do You Need to Build a Facility? If YES, How Much will it cost?

Flora Shawn® Peanut Butter Company, Inc. will not build a new facility for our peanut butter making company; we intend to start with a long-term lease and after 8 years, we will start the process of acquiring our own shop.

d. What are the Ongoing Expenses for Running a Peanut Butter Making Company?

- Rent or mortgage

- Utilities (such as electricity, gas, water, and internet service)

- Equipment maintenance and repair (such as harvesting equipment, processing machinery, or packaging equipment)

- Staffing costs (employee salaries, benefits, payroll taxes, and workers’ compensation insurance)

- The cost of purchasing peanuts

- Packaging and Shipping

- Marketing and advertising

- Accounting and legal fees (such as bookkeeping, tax preparation, and contract review).

e. What is the Average Salary of your Staff?

- Chief Executive Officer – $68,000 Per Year

- Production Manager – $45,000 per year

- Quality Control Staff – $40,000 per year

- Administrative Assistant (Cashier) – $35,000 per year

- Processing and Production Staff – $33,000 per year

- Logistics and Shipping Staff – $32,000 per year

- Customer Service Executive -$30,000 per year.

f. How Do You Get Funding to Start a Peanut Butter Making Business?

- Raising money from personal savings and sale of personal stocks and properties

- Raising money from investors and business partners

- Sell shares to interested investors

- Applying for a loan from your bank/banks

- Pitching your business idea and applying for business grants and seed funding from the government, donor organizations, and angel investors

- Source for soft loans from your family members and friends.

Financial Projection

A. how much should you charge for your product/service.

The price of peanut butter in the United States can vary depending on various factors such as brand, size, type (regular, organic, natural), and location of purchase. Generally, peanut butter prices range from around $2 to $10 or more, depending on the factors mentioned above.

b. Sales Forecast?

- First Fiscal Year (FY1): $345,000

- Second Fiscal Year (FY2): $460,000

- Third Fiscal Year (FY3): $570,000

c. Estimated Profit You Will Make a Year?

- First Fiscal Year (FY1) (Profit After Tax): 20%

- Second Fiscal Year (FY2) (Profit After Tax): $25%

- Third Fiscal Year (FY3) (Profit After Tax): 30%

d. Profit Margin of a Peanut Butter Making Company Product/Service

The ideal profit margin we hope to make at Flora Shawn® Peanut Butter Company, Inc. will be between 15 and 30 percent depending on the packaging size.

Growth Plan

A. how do you intend to grow and expand by opening more retail outlets/offices or selling a franchise.

Flora Shawn® Peanut Butter Company, Inc. will grow our peanut butter making manufacturing company by first opening other production plants in key cities in the United States of America within the first five years of establishing the business and then will start expanding overseas.

b. Where do you intend to expand to and why?

Flora Shawn® Peanut Butter Company, Inc. plans to expand to the following cities.

- Orlando, Florida

- Nashville, Tennessee

- San Francisco, California

- Phoenix, Arizona

- Austin, Texas

- Denver, Colorado

- Seattle, Washington

- Charlotte, North Carolina

- Atlanta, Georgia

- Dallas, Texas.

We are expanding to these cities because these cities have a high demand for peanut butter.

The founder of Flora Shawn® Peanut Butter Company, Inc. plans to exit the business via family succession. We have positioned structures and processes in place that will help us achieve our plan of successfully transferring the business from one family member to another and from one generation to another without difficulties.

The company has successfully developed a detailed transition plan to smoothly hand over responsibilities to the new successor. This includes transferring ownership, training key personnel, and communicating with employees, customers, and suppliers about the change..

Business Ideas

Investment Ideas

Make Money at Home

- Bitcoin and Xcoins

- Earn On Social Networking

- Freelancing

- Make a Website

- Money Making Apps

- Affiliate Marketing

- Online Surveys

- Start a Blog

- Web Hosting

Startup Ideas

- Your Passion Your Money

Make Money Online

Peanut Butter Making Business Plan: Equipment, Cost, and Profit

Table of contents, understanding the licensing requirements for peanut butter manufacturing business, exploring the costs involved in starting a peanut butter manufacturing business, analyzing the profit potential of a peanut butter manufacturing business, obtaining the necessary licenses and permits for peanut butter production, estimating the initial investment required to start a peanut butter manufacturing business, identifying the equipment and machinery needed for peanut butter production, determining the raw material costs for peanut butter manufacturing, assessing the labor and operational expenses in running a peanut butter manufacturing business, evaluating the marketing and distribution strategies for peanut butter products, understanding the regulatory compliance and quality control measures in peanut butter manufacturing.

Peanut butter is becoming more popular because it’s good for you and can be used in lots of different foods. With many people inquiring about how to start a peanut butter-making business, the potential for entrepreneurs to venture into this industry is vast. Whether you’re interested in small-scale peanut butter production or looking to explore a larger-scale setup, it’s crucial to have a comprehensive peanut butter business plan.

Key concerns like “How much does it cost to start a peanut butter business?”, “Is peanut butter manufacturing profitable?” “What are the requirements for peanut butter business?” and the intricacies of the roasted peanut business plan can all be addressed with accurate research and planning.

Peanut Butter Making Business Plan

Before diving into the peanut butter manufacturing business, knowing the licensing requirements is essential. You must obtain licenses from local health departments and food safety authorities to ensure that your peanut butter meets health and safety standards. These licenses will allow you to produce and sell your peanut butter legally.

Having them not only gives your business credibility but also ensures the safety and well-being of your customers. Part of the peanut butter manufacturing business plan license cost to start and profits is acquiring the needed permits, which varies by region and country.

One of the fundamental aspects of a peanut butter business plan is understanding the costs involved. The total cost largely depends on the scale of production. While small-scale peanut butter production may require a modest investment, scaling up to industrial levels would demand significantly more capital. Key expenses include the cost of raw peanuts, equipment, packaging, branding, and distribution. Additionally, rent, electricity, and labor costs should be accounted for.

Is peanut butter manufacturing profitable? The short answer is yes. However, the profit margins are influenced by factors like production scale, marketing strategy, and distribution network. On average, the profit margin in the peanut butter business can range from 20% to 40% based on factors like brand positioning, quality, and consumer demand. An entrepreneur can achieve significant returns on investment with effective strategies and a well-executed peanut butter business plan.

In case you missed it: How to Start Gold Import-Export Business in India: A Step-by-Step Profitable Guide for Beginners

Acquiring the right licenses and permits is crucial for a smooth-running peanut butter manufacturing business. These licenses validate the quality and safety of your product and ensure that your business operates without any legal hitches. You may need permits from agricultural, health, and food safety departments, depending on your location. Make sure to do good research and talk to local officials to know exactly what your area needs.

The initial investment for a peanut butter manufacturing business largely depends on the production scale and location. The startup costs for small-scale peanut butter production range from $5,000 to $20,000. This covers the cost of equipment, raw materials, and minimal branding. However, the peanut butter manufacturing plant cost can rise to $100,000 or more for a larger setup, incorporating advanced machinery, larger facilities, and more extensive marketing and distribution channels.

You’ll require specific equipment and machinery to kickstart your peanut butter-making business. At the core of production are the roasting and grinding machines. Roasters are used to get the roasted peanut flavor passed through grinders to achieve the desired peanut butter consistency. Other essential equipment includes sorting machines (for selecting quality peanuts), de-shelling, and packaging machines. Investing in automated machines can streamline the production process and enhance efficiency if aiming for a larger-scale operation.

The cornerstone of peanut butter manufacturing lies in the quality and cost of raw materials. Peanuts are the primary raw material, accounting for the most significant portion of production costs. The price of peanuts can vary based on factors such as seasonality, geographic location, and market demand. Beyond peanuts, additional ingredients like salt, sweeteners, or preservatives might be added depending on the desired product recipe.

Packaging materials such as jars, lids, and labels also contribute to raw material costs. To ensure consistent product quality and profitability, businesses must maintain steady relationships with reliable suppliers, explore bulk purchase discounts, and regularly monitor market prices.

Labor and operational expenses play a pivotal role in determining the profitability of a peanut butter manufacturing venture. Labor costs encompass salaries and wages for employees involved in various stages, from procurement to packaging. As the production scale increases, automation might reduce labor costs, but it introduces machinery maintenance expenses.

Operational costs are expenses such as water and electricity bills, rent or mortgage for the place where we make things, and the expenses of storing and managing our stuff. An efficient operational strategy focuses on optimizing production cycles, reducing waste, and maintaining a trained and motivated workforce to ensure a smooth and cost-effective manufacturing process.

In case you missed it: 12 Best Paper Cup Manufacturers in India

Once the peanut butter is manufactured, effective marketing and distribution become paramount to its success in the market. Marketing strategies should be crafted considering the target audience, brand positioning, and competitive landscape. Activities could include digital marketing campaigns, in-store promotions, and participation in food expos.

The distribution strategy involves choosing between direct-to-consumer channels or partnering with retailers and wholesalers. Both approaches come with their own set of advantages and costs. Direct sales might offer higher profit margins, while retailers provide broader market access. Regular evaluation and adaptation of these strategies based on market feedback and sales performance ensure sustained growth and product reach.

Adherence to regulatory compliance and strict quality control is non-negotiable in the food manufacturing sector. Every country or region will have its regulations governing food production and safety, and peanut butter is no exception. Manufacturers must ensure that their products meet stipulated safety and quality standards, which might entail periodic inspections and certifications from relevant authorities.

Quality control measures involve setting up in-house testing processes, from checking the quality of raw peanuts to the final product’s texture and taste. A robust quality control system ensures regulatory compliance and builds consumer trust and brand reputation in the market.

In case you missed it: 10 Profitable Disposable-Based Business Ideas: Low-cost and Low-Investment

Navigating the intricacies of peanut butter manufacturing requires meticulous planning and a keen understanding of market dynamics. With the right strategies and adherence to quality and regulations, entrepreneurs can tap into the growing demand and achieve sustainable profitability.

Handicraft Making at Home: A Small Profitable Business Idea

Pet-tech startups: innovations for animal lovers, tech repair services: meeting the demand for gadget maintenance, maximizing rewards: smart credit card habits for cashback and points, ultimate guide to making money from goat milk business, how to start an agricultural value added product business.

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

10 value-added business ideas for millets: low-investment and highly profitable, leave a reply cancel reply.

Save my name and email in this browser for the next time I comment.

Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with...

Why cleaning service business becoming more profitable in metro cities in india, 10 best businesses to start in ayodhya for profits, top drone business ideas in india: unlocking aerial innovation & opportunities, top 10 service businesses you can start with no money, ultimate guide to starting a home-based advertising agency business, starting a nail salon near your location: check list, business plan, licensing,..., construction company name ideas: guide to create new construction company names, 8 best small businesses to start in hyderabad: low-cost and profitable, 10 best small businesses to start in massachusetts: low-cost and profitable, 10 best small businesses to start in maryland: low-investment and profitable, 10 best small businesses to start in delaware: low-investment and profitable, ideas to make money in india – a full guide, mudra yojana loan scheme, eligibility, how to apply, profit in dry fruit business (cost to start), how to make money from rice mill business in india, profitable agriculture business ideas in india, government loans for women entrepreneurs in india.

- Solutions Peanut Butter Solution Peanut Roasting Solution Peanut Frying Solution Peanut Cutting Solution

- Product Peanut Roasting Machines Peanut Peeling Machines Peanut Butter Machines Peanut Frying Machines Peanut Cutting Machine Peanut Oil Machines Peanut Flavoring Machines Peanut Packing Machines

Peanut Butter Processing Business Plan - Step-by-Step Guide

- Release Lime: Apr 18 2023

- Source: admin

Share This:

- Pre: Peanut Butter Manufacturing Process in Industry

- Next: Peanut Butter Making Machine in Used in South Africa

Your contact information will not be published. Required fields are marked*

How to Write a Business Plan for Peanut Butter Production That Succeeds

Get Full Bundle

| $169$99 | $59$39 | $39$29 | $15$9 | $25$15 | $15$9 | $15$9 | $15$9 | $19 |

Launching a successful peanut butter production business requires meticulous planning and preparation. Before diving into your business plan, it's crucial to complete a comprehensive checklist that covers essential steps, from market research to financial feasibility. This concise guide outlines the 9 crucial steps you must tackle to set the foundation for your peanut butter venture and position it for long-term success.

Steps Prior To Business Plan Writing

Before embarking on the journey of writing a comprehensive business plan for a peanut butter production venture, it is crucial to lay the groundwork and address several key considerations. This checklist outlines the essential steps to be taken to ensure a well-informed and strategic approach to your business plan development.

| Step | Key Considerations |

|---|---|

| Conduct market research and analyze industry trends | Gather data on market size, growth potential, consumer preferences, and competitive landscape. Identify emerging trends and opportunities within the peanut butter industry. |

| Identify target customers and their preferences | Develop a clear understanding of your target audience, including their demographics, purchasing habits, and specific needs or pain points that your peanut butter product can address. |

| Determine unique selling proposition and competitive advantages | Identify the unique features, qualities, or benefits that set your peanut butter apart from competitors, such as organic, all-natural ingredients, innovative flavors, or specialized packaging. |

| Assess production capabilities and resource requirements | Evaluate your production capacity, equipment, and personnel needs to ensure you can meet the anticipated demand for your peanut butter. Determine the necessary investments in facilities, machinery, and labor. |

| Evaluate potential suppliers and logistics for raw materials | Identify reliable and cost-effective suppliers for peanuts, oils, and other ingredients. Assess the logistics of sourcing, storing, and transporting the raw materials to your production facility. |

| Develop brand identity and packaging design | Create a distinctive and appealing brand identity, including a name, logo, and visual elements that reflect the quality and positioning of your peanut butter product. Determine the optimal packaging design that aligns with your brand and meets industry standards. |

| Investigate regulatory requirements and obtain necessary licenses | Research the applicable food safety regulations, labeling requirements, and any necessary licenses or permits for operating a peanut butter production business in your jurisdiction. |

| Assess financial feasibility and potential funding sources | Develop financial projections, including start-up costs, production expenses, marketing budgets, and revenue forecasts. Identify potential funding sources, such as business loans, investor funding, or government grants, to support your peanut butter venture. |

| Assemble a skilled team with relevant expertise | Identify and recruit individuals with relevant experience in areas such as production, quality control, marketing, and finance to form a capable and well-rounded team to drive the success of your peanut butter business. |

Conduct market research and analyze industry trends

Before embarking on your peanut butter production business, it is crucial to conduct thorough market research and analyze the industry trends. This step will provide you with valuable insights into the current landscape, potential opportunities, and challenges that may arise. By understanding the market dynamics, you can develop a well-informed business plan that aligns with the needs and preferences of your target customers.

Start by examining the peanut butter industry as a whole. Analyze the market size , growth projections, and key trends driving consumer demand. According to industry reports, the global peanut butter market is expected to reach a value of $8.9 billion by 2025 , growing at a CAGR of 4.8% from 2020 to 2025. This growth is largely attributed to the increasing health consciousness among consumers and the rising popularity of organic and natural peanut butter products.

Delve deeper into the target market for your peanut butter business. Identify the demographic and psychographic characteristics of your ideal customers, such as age, income level, health concerns, and purchasing behaviors. This information will help you tailor your products and marketing strategies to meet their specific needs and preferences.

- Conduct online surveys, focus groups, or interviews to gather firsthand insights from potential customers about their peanut butter consumption habits and preferences.

- Analyze industry reports and market research data to understand the latest trends, such as the growing demand for organic, all-natural, and specialty peanut butter products.

- Investigate the competitive landscape by researching the offerings, pricing, and marketing strategies of established peanut butter brands in your target market.

Additionally, assess the regulatory environment and any industry-specific requirements that may impact your peanut butter production business. This could include food safety regulations, labeling guidelines, and environmental standards that you need to adhere to.

By conducting thorough market research and analyzing industry trends, you can make informed decisions about your peanut butter production business, including product development, pricing, marketing, and operational strategies. This critical step will help you build a solid foundation for your business plan and increase your chances of success in the competitive peanut butter market.

| Peanut Butter Production Business Plan Get Template |

Identify Target Customers and Their Preferences

Identifying your target customers and understanding their preferences is a critical step in developing a successful business plan for peanut butter production. By conducting thorough market research, you can gain valuable insights into the specific needs and expectations of your potential customers, which will inform every aspect of your peanut butter business, from product development to marketing and sales strategies.

According to the Specialty Food Association , the peanut butter market is expected to grow at a CAGR of 4.5% from 2021 to 2026 , driven by the increasing demand for healthier and more sustainable food options. The organic peanut butter segment is particularly promising, with a projected growth rate of 7.8% during the same period .

To identify your target customers for Spread Delight Peanut Butter Co., start by analyzing the demographic and psychographic profiles of health-conscious consumers who are likely to be interested in your organic, additive-free peanut butter. Consider factors such as age, income, education level, lifestyle preferences, and values. For example, you may find that your target customers are primarily millennials and Gen Z individuals who are concerned about the environmental impact of their food choices and are willing to pay a premium for high-quality, sustainable products.

- Conduct in-depth surveys and interviews with potential customers to understand their pain points, preferences, and willingness to pay for your peanut butter products.

- Analyze online reviews and discussions about existing peanut butter brands to identify the key features and attributes that are most important to your target audience.

- Leverage social media and online forums to engage with your target customers, gather feedback, and refine your product offerings and marketing strategies.

Once you have a clear understanding of your target customers' preferences, you can develop a unique selling proposition (USP) that sets your peanut butter products apart from the competition. This may involve highlighting the use of organic, sustainable ingredients, the absence of artificial additives, or the incorporation of unique flavor profiles that cater to the health-conscious consumer.

By aligning your peanut butter production capabilities and resource requirements with the preferences of your target customers, you can ensure that your business plan is well-positioned to capture a significant share of the growing specialty foods market and achieve long-term success.

Determine Unique Selling Proposition and Competitive Advantages

As you embark on your peanut butter production journey, it's crucial to define your unique selling proposition (USP) and identify your competitive advantages. This step will help you differentiate your brand and products in the crowded peanut butter market, which is expected to reach a global value of $4.6 billion by 2028 , growing at a CAGR of 5.2% .

To determine your USP, start by conducting a thorough analysis of the peanut butter industry. Examine the current market trends, consumer preferences, and the offerings of your competitors. What sets your peanut butter apart from the rest? Perhaps it's your commitment to using organic, non-GMO ingredients , or your innovative flavor profiles that cater to health-conscious consumers. Alternatively, you might offer superior sustainability practices or a unique product experience that resonates with your target audience.

- Conduct a SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis to identify your competitive advantages and potential areas for differentiation.

- Gather customer feedback and insights to understand their pain points and preferences, which can inform your USP development.

- Research industry benchmarks and best practices to ensure your USP aligns with evolving consumer trends and market demands.

Once you have a clear understanding of your USP, it's time to translate it into a compelling brand identity and marketing strategy. Develop a distinctive brand name, logo, and packaging design that effectively communicate your value proposition to your target customers. Consistently reinforce your USP across all touchpoints, from your website and social media presence to your product labeling and customer interactions.

Remember, your USP should not only differentiate your peanut butter from the competition, but also resonate with your ideal customers. By crafting a strong, unique selling proposition, you'll be better positioned to capture a significant share of the growing peanut butter market and establish your brand as a preferred choice among health-conscious consumers.

Assess production capabilities and resource requirements

Evaluating your production capabilities and resource requirements is a crucial step in the peanut butter production business plan. This assessment will help you determine the feasibility of your operations and identify any potential bottlenecks or areas that require additional investment.

To assess your production capabilities, start by analyzing your existing equipment, facilities, and workforce. Determine the maximum output you can achieve with your current resources, and identify any areas where you may need to expand or upgrade. Consider factors such as production capacity, processing speed, and quality control measures.

Next, assess the resource requirements for your peanut butter production. This includes the raw materials, such as peanuts, oils, and any other ingredients, as well as the packaging materials, labeling, and other supplies. Estimate the quantities and costs of these resources, and research potential suppliers to ensure a reliable and cost-effective supply chain.

- Tip: Conduct a thorough analysis of your production capacity and resource requirements to identify any potential constraints or areas for improvement. This will help you optimize your operations and ensure the long-term sustainability of your peanut butter business.

Another important aspect to consider is the labor requirements for your peanut butter production. Determine the number of employees you'll need to handle various tasks, such as processing, packaging, and quality control. Factor in the costs of wages, benefits, and any necessary training or certifications.

Additionally, evaluate the energy and utilities requirements for your peanut butter production, including electricity, water, and any specialized equipment or machinery. Estimate the associated costs and ensure that your facility can accommodate the necessary infrastructure.

By thoroughly assessing your production capabilities and resource requirements, you'll be able to develop a comprehensive understanding of the operational and financial feasibility of your peanut butter production business. This information will be crucial in crafting a robust and well-informed business plan that can attract investors and support the growth of your 'Spread Delight Peanut Butter Co.'

- Tip: Consider incorporating sustainable and eco-friendly practices into your peanut butter production, such as using renewable energy sources or implementing waste reduction strategies. This can not only benefit the environment but also align with the values of your health-conscious target market.

According to the Specialty Food Association, the global peanut butter market is expected to grow at a CAGR of 6.5% from 2021 to 2028 , reaching a value of $6.9 billion by 2028 . By carefully evaluating your production capabilities and resource requirements, you can position your 'Spread Delight Peanut Butter Co.' to capitalize on this expanding market opportunity and deliver a superior, sustainable peanut butter product to your customers.

| Peanut Butter Production Financial Model Get Template |

Evaluate Potential Suppliers and Logistics for Raw Materials

Establishing a reliable supply chain is crucial for the success of your peanut butter production business. As you embark on this journey, it is essential to thoroughly evaluate potential suppliers and logistics for your raw materials. This step will help you ensure a steady flow of high-quality ingredients, minimize production disruptions, and optimize your operational costs.

Start by conducting a comprehensive market analysis to identify reputable peanut suppliers in your region or beyond. Look for suppliers that can consistently provide large quantities of high-quality, organic peanuts at competitive prices. Consider factors such as their production capacity, delivery times, and commitment to sustainable practices.

- Reach out to multiple suppliers to compare their offerings and negotiate the best terms for your business.

- Establish long-term relationships with your suppliers to ensure a reliable supply and potentially negotiate better pricing.

- Explore the feasibility of diversifying your supplier base to mitigate risks and maintain a steady flow of raw materials.

Next, assess the logistics of transporting your raw materials from the suppliers to your production facility. Evaluate factors such as transportation modes, delivery schedules, and potential storage requirements. Consider the cost of freight, fuel surcharges, and any additional logistics fees to ensure your overall supply chain costs remain within your budget.

Depending on the scale of your peanut butter production, you may need to explore the feasibility of renting or leasing storage facilities to accommodate large shipments of peanuts. This can help you maintain an adequate inventory and minimize the risk of supply chain disruptions.

- Explore the possibility of negotiating volume discounts or favorable shipping rates with your transportation providers.

- Investigate the availability of government or industry-specific programs that offer incentives or subsidies for logistics and transportation costs.

- Implement a robust inventory management system to track your raw material levels and proactively address any potential shortages.

By carefully evaluating your potential suppliers and logistics, you can ensure a steady supply of high-quality peanuts, optimize your operational costs, and position your peanut butter production business for long-term success.

Develop Brand Identity and Packaging Design

Crafting a strong brand identity and captivating packaging design is a crucial step in the peanut butter production business plan. Your brand will serve as the foundation for your product's perception in the market, influencing consumer loyalty and purchase decisions. Similarly, your packaging design plays a vital role in attracting and engaging your target audience.

Begin by conducting thorough market research to understand the preferences and expectations of your target customers. Analyze the branding and packaging strategies of your competitors to identify opportunities for differentiation. Leverage this insights to develop a unique and memorable brand identity that resonates with your audience.

- Establish a strong brand name that is easy to remember and reflects your product's essence.

- Create a visually appealing logo that captures the essence of your peanut butter brand.

- Develop a cohesive brand color palette and typography that enhance your brand's visual identity.

Your packaging design should not only protect the product but also effectively communicate your brand's story and values. Consider factors such as material, shape, size, and labeling to ensure your peanut butter packaging is both functional and visually striking. Incorporate design elements that highlight your product's unique selling points, such as organic, natural, or sustainable attributes.

- Opt for high-quality, sustainable packaging materials that align with your brand's eco-friendly positioning.

- Incorporate eye-catching graphics, imagery, and typography that instantly grab the attention of your target consumers.

- Ensure your packaging design is consistent across all marketing touchpoints, from your website to in-store displays.

According to a study by the Packaging Association, 82% of consumers are more likely to purchase a product with an appealing and innovative packaging design. Additionally, 72% of consumers believe that the packaging of a product reflects the quality of the brand. By investing in a strong brand identity and captivating packaging, you can differentiate your peanut butter from the competition and create a lasting impression with your target audience.

Investigate Regulatory Requirements and Obtain Necessary Licenses

When starting a peanut butter production business, it is crucial to navigate the complex regulatory landscape and obtain the necessary licenses and permits. This step ensures compliance with food safety standards, protects consumer health, and avoids potential legal pitfalls that could derail your business operations.

The first step in the regulatory process is to research the specific requirements in your local and state jurisdictions. This may include registering your business, obtaining a food production license, and complying with labeling and packaging regulations. According to the U.S. Food and Drug Administration (FDA), all commercial food facilities must register as a 'food facility' and renew their registration every other year.

- Familiarize yourself with the FDA's Current Good Manufacturing Practices (CGMPs) for food manufacturing to ensure your production processes and facilities meet the required standards.

- Investigate any additional state or local regulations related to peanut butter production, such as health department inspections, zoning requirements, and environmental permits.

- Consult with a legal professional who specializes in food and beverage regulations to ensure you have a comprehensive understanding of all the necessary licenses and permits.

In addition to the basic business and food production licenses, you may also need to consider specialized permits, such as those related to the handling and storage of peanuts and other allergens. The Food Allergen Labeling and Consumer Protection Act (FALCPA) requires clear labeling of the top eight food allergens, including peanuts, on all packaged food products. Ensuring compliance with these regulations will protect your customers and demonstrate your commitment to food safety.

Obtaining the necessary licenses and permits can be a time-consuming and complex process, but it is essential for the long-term success and viability of your peanut butter production business. By proactively addressing these regulatory requirements, you can avoid costly delays, fines, or even the shutdown of your operations, allowing you to focus on the growth and development of your brand.

| Peanut Butter Production Pitch Deck |

Assess Financial Feasibility and Potential Funding Sources

Evaluating the financial feasibility of your peanut butter production business is a crucial step in the business planning process. This assessment will help you determine the viability of your venture and identify potential funding sources to support your startup and growth.