- Oct 13, 2019

10 Steps to Problem Solving for Engineers

Updated: Dec 6, 2020

With the official launch of the engineering book 10+1 Steps to Problem Solving: An Engineer's Guide it may be interesting to know that formalization of the concept began in episode 2 of the Engineering IRL Podcast back in July 2018.

As noted in the book remnants of the steps had existed throughout my career and in this episode I actually recorded the episode off the top of my head.

My goal was to help engineers build a practical approach to problem solving.

Have a listen.

Who can advise on the best approach to problem solving other than the professional problem solvers - Yes. I'm talking about being an Engineer.

There are 2 main trains of thought with Engineering work for non-engineers and that's trying to change the world with leading edge tech and innovations, or plain old boring math nerd type things.

Whilst, somewhat the case what this means is most content I read around Tech and Engineering are either super technical and (excruciatingly) detailed. OR really riff raff at the high level reveling at the possibilities of changing the world as we know it. And so what we end up with is a base (engineer only details) and the topping (media innovation coverage) but what about the meat? The contents?

There's a lot of beauty and interesting things there too. And what's the centrepiece? The common ground between all engineers? Problem solving.

The number one thing an Engineer does is problem solving. Now you may say, "hey, that's the same as my profession" - well this would be true for virtually every single profession on earth. This is not saying there isn't problem solving required in other professions. Some problems require very basic problem solving techniques such is used in every day life, but sometimes problems get more complicated, maybe they involve other parties, maybe its a specific quirk of the system in a specific scenario. One thing you learn in engineering is that not all problems are equal. These are

The stages of problem solving like a pro:

Is the problem identified (no, really, are you actually asking the right question?)

Have you applied related troubleshooting step to above problem?

Have you applied basic troubleshooting steps (i.e. check if its plugged in, turned it on and off again, checked your basics)

Tried step 2 again? (Desperation seeps in, but check your bases)

Asked a colleague or someone else that may have dealt with your problem? (50/50 at this point)

Asked DR. Google (This is still ok)

Deployed RTFM protocol (Read the F***ing Manual - Engineers are notorious for not doing this)

Repeated tests, changing slight things, checking relation to time, or number of people, or location or environment (we are getting DEEP now)

Go to the bottom level, in networking this is packet sniffers to inspect packets, in systems this is taking systems apart and testing in isolation, in software this is checking if 1 equals 1, you are trying to prove basic human facts that everyone knows. If 1 is not equal to 1, you're in deep trouble.At this point you are at rebuild from scratch, re install, start again as your answer (extremely expensive, very rare)

And there you have it! Those are your levels of problem solving. As you go through each step, the more expensive the problem is. -- BUT WAIT. I picked something up along the way and this is where I typically thrive. Somewhere between problem solving step 8 and 10.

The secret step

My recommendation at this point is to try tests that are seemingly unrelated to anything to do with the problem at all.Pull a random cable, test with a random system off/on, try it at a specific time of the day, try it specifically after restarting or replugging something in. Now, not completely random but within some sort of scope. These test are the ones that when someone is having a problem when you suggest they say "that shouldn't fix the problem, that shouldn't be related" and they are absolutely correct.But here's the thing -- at this stage they have already tried everything that SHOULD fix the problem. Now it's time for the hail mary's, the long shots, the clutching at straws. This method works wonders for many reasons. 1. You really are trying to try "anything" at this point.

2. Most of the time we may think we have problem solving step number 1 covered, but we really don't.

3. Triggering correlations.

This is important.

Triggering correlations

In a later post I will cover correlation vs causation, but for now understand that sometimes all you want to do is throw in new inputs to the system or problem you are solving in order to get clues or re identify problems or give new ways to approach earlier problem solving steps. There you have it. Problem solve like a ninja. Approach that extremely experienced and smart person what their problem and as they describe all the things they've tried, throw in a random thing they haven't tried. And when they say, well that shouldn't fix it, you ask them, well if you've exhausted everything that should have worked, this is the time to try things that shouldn't. Either they will think of more tests they haven't considered so as to avoid doing your preposterous idea OR they try it and get a new clue to their problem. Heck, at worst they confirm that they do know SOMETHING about the system.

Go out and problem solve ! As always, thanks for reading and good luck with all of your side hustles.

If you prefer to listen to learn we got you covered with the Engineering IRL show!

For Youtube please go to:

https://youtu.be/EHaRNZhqmHA

For Spotify please go to:

https://open.spotify.com/show/3UZPfOvNwQkaCA1jLIOxp4

And don't forget to subscribe if you get any value from the Engineering IRL Content

- Technical Tactics

- 10+1 Steps to Problem Solving

Recent Posts

How to Implement OSHA’s Requirement of Emergency Medical Services in Construction

Preventing Noise-Induced Issues in Construction

The Advantages of CAD for Modern Engineers

Get your free Engineering Toolkit for Engineering IRL listeners only

Get a copy of the Operational Technology Ultimate Guide for Engineers e-book for free.

The Engineering Method: A Step-by-Step Process for Solving Challenging Problems

Getting stuck before you even begin to work on an engineering problem is more common than you think. Use this method to help you break a problem down, find a path toward a solution, and avoid mistakes.

Have you ever experienced the feeling of panic when presented with a problem you’ve never seen before, you’re on a deadline, and all eyes are on you? Maybe it’s your manager asking you to work on something urgent and mission-critical, or in an interview for your dream job and you’re across the table from the one person standing in your way of getting the offer. Most of us have felt this moment of panic at some point or another. In my experience as a tech lead and engineering manager at companies like Microsoft and Meta (then Facebook), the people who are most successful in these situations aren’t always the ones who are the smartest or have the most experience. Rather, it’s the people who used effective strategies for solving problems they hadn’t seen before. The junior engineers who do this well build experience and grow quickly. The higher-level engineers who have honed these skills are the key players on their teams and are often the best equipped to mentor the junior engineers. But how do people consistently make progress when working on something new and challenging? What do you do when you really have no idea where to start? We created The Engineering Method , a simple set of steps that can help you break a problem down, find a path toward a solution, and avoid mistakes. Here at Formation, we apply the method to software engineering problems, but the same steps can be applied to many different fields.

Step 1: Thoroughly understand the problem

A. ask clarifying questions.

Good questions often fall into one of two categories. They’re either questions that:

- Gather requirements to precisely understand what the goal is or isn’t

- Search for subtle edge cases or exceptions to the rules of the problems

B. Come up with your own “happy case” examples

A “happy case” refers to a normal input that isn’t trying to test the edge cases of the question. Happy path and “golden path” are also terms used to describe this. What does the feature, algorithm, or system need to do in the normal cases? What do these normal cases look like? At this stage, you are using the information gathered to and testing your understanding. You want to be able to generate 2-3 more examples that illustrate the requirements. These examples are going to help you find the patterns that will lead you towards possible approaches.

C. Come up with edge cases

Once you’ve come up with some “happy cases” and understand the problem, test the limits. Try not to go straight to the easy ones like, “what if it’s null”. This is useful for the implementation but is unlikely to inform the algorithm. Instead, try to think about logical edge cases that are more unique to that specific problem. Some edge cases are easier to deal with in some designs versus others. Listing out these edge cases now will help you choose between multiple implementation options later. For an algorithmic problem, here are some of the most common categories of edge cases:

- Negative numbers

- Empty cases (Empty array, string)

- Out of bounds

- Cycles in lists

- In problems with arrays or matrices, often the literal edges of the data have interesting quirks

Step 2: Identify and explore possible solutions

Always try to identify multiple solutions. Weigh the pros and cons of the different solutions and then select one to try. Sometimes, an attempt doesn’t end up working out, but the data gathered from these unsuccessful ideas often informs better ideas. For example, let’s say you’re attempting to solve something with depth-first search. While testing the idea on an example, you might discover that it doesn’t work. The way it doesn’t work might lead you to discover that breadth-first search does work. Keeping your work on these unsuccessful ideas might help inform your eventual correct solution.

A. Identify a simple solution

Try the simple thing first. If no obvious solution comes to you right away, work through a list of major solution archetypes for the type of problem.

- Algorithmic problem: stack, queue, BFS, DFS, dynamic programming, etc.

- Systems: map/reduce, key/value store, work queue

B. Work through some example cases manually

Take the sample input or ideas from the exploration phase and try to solve it manually. As you solve it, try to see if you can generalize your decisions. If you can't, try making small variations to your input or using input ideas from Step 1 to see if you can identify the patterns.

C. Work out the expected time and space complexity of each idea

Runtime and space complexity is one important part of comparing solutions. Often, but not always, we want to implement the solution with optimal complexity.

Step 3: Choose a solution

A big part of engineering is making decisions and choosing between different implementation options. Proactively point out the advantages/disadvantages of your ideas. If there is more than one solution on the table, you should consider which makes the most sense build. Often, there is no one best answer, so think about trade-offs and discuss the reasoning behind your decision with your team. Consider time/space complexity, but remember this is only one consideration. You should also consider difficulty of implementation. Remember, simple solutions are often best, especially in a time crunch.

Step 4: Make a plan

You’ve decided on a basic approach, an algorithm, or a high-level system design. It’s time to build it now, right? Not quite. Even for simple problems, a little bit of planning can go a long way. For something small, it might be as simple as splitting out some helper functions. Oftentimes, just starting at the top can lead to confusion and bugs. Starting with small, testable building blocks is often better.

Step 5: Build it

At this point, with a clear understanding of the solution and an implementation plan, the actual coding will go much more smoothly. As problems become more difficult, it becomes more and more important to explicitly split out these steps. Doing so will avoid costly mistakes and, while it feels slow, it will often be much faster in the long run. For problems that seem simple enough that you can effectively jump into coding quickly, remember that you’ve not actually skipped the preceding steps. You just did them ahead of time in your past work or practice and are utilizing that past experience.

Step 6: Test it

You've written a solution. You're done. Right? NO. As an engineer, you are always responsible for the results and quality of your work. As you uncover potential issues, you will be moving back and forth between 4 and 5. The good news in this step is that you should have already done most of the work! Some test cases should have come from Steps 1 and 2.

A. Test the happy cases

Start with a standard happy case . For example, for sorting, you might test a standard unsorted array: [3, 5, 4, 1, 2]. Pick a few important test cases you have identified earlier in Steps 2 and 3.

B. Test the edge cases

You should be picking from edge cases that you already identified earlier. Once you’ve written the code, you may also discover some implementation-level edge cases. A good way to make sure that you’ve covered all edge cases is to ensure that every line of code is executed at least once ! This is also the time to handle truly malformed input.

Wrapping Up

As engineers, our job is to bring new ideas to life. This often means doing something new, something different than we’ve done before, or maybe even building something that has never existed before. This means we can expect to encounter problems we haven’t seen previously. Experience can build some intuition that can seep things up, but the people who solve new problems the best are the ones who can make progress even when experience and intuition can’t help. Feeling panic set in? Take a deep breath, then follow the Engineering Method. Looking for structure in your job hunt? Apply below to close your most urgent interviewing skill gaps and interview with confidence.

LeetCode Alternatives: Top platforms for coding practice

An overview of transactions and acid properties for relational databases with algojs, an overview of relational databases with algojs.

- What is Chemical and Biological Engineering?

- Engineering problem solving

- Error and uncertainty

- Process variables

- Process Fundamentals

- Material Balances

- Reacting systems

- Reaction kinetics

- Reactor design

- Bioreactors

- Fluids and fluid flow

- Mass transfer

- Energy balances

- Heat transfer

- Heat exchangers

- Mechanical energy balances

- Process safety

- Engineering ethics

- Sustainability

- Engineering in a global context

- How ‘good’ a solution do you need

- Steps in solving well-defined engineering process problems, including textbook problems

- « What is Chemi...

- Teamwork »

Engineering Problem Solving ¶

Some problems are so complex that you have to be highly intelligent and well-informed just to be undecided about them. —Laurence J. Peter

Steps in solving ‘real world’ engineering problems ¶

The following are the steps as enumerated in your textbook:

Collaboratively define the problem

List possible solutions

Evaluate and rank the possible solutions

Develop a detailed plan for the most attractive solution(s)

Re-evaluate the plan to check desirability

Implement the plan

Check the results

A critical part of the analysis process is the ‘last’ step: checking and verifying the results.

Depending on the circumstances, errors in an analysis, procedure, or implementation can have significant, adverse consequences (NASA Mars orbiter crash, Bhopal chemical leak tragedy, Hubble telescope vision issue, Y2K fiasco, BP oil rig blowout, …).

In a practical sense, these checks must be part of a comprehensive risk management strategy.

My experience with problem solving in industry was pretty close to this, though encumbered by numerous business practices (e.g., ‘go/no-go’ tollgates, complex approval processes and procedures).

In addition, solving problems in the ‘real world’ requires a multidisciplinary effort, involving people with various expertise: engineering, manufacturing, supply chain, legal, marketing, product service and warranty, …

Exercise: Problem solving

Step 3 above refers to ranking of alternatives.

Think of an existing product of interest.

What do you think was ranked highest when the product was developed?

Consider what would have happened if a different ranking was used. What would have changed about the product?

Brainstorm ideas with the students around you.

Defining problems collaboratively ¶

Especially in light of global engineering , we need to consider different perspectives as we define our problem. Let’s break the procedure down into steps:

Identify each perspective that is involved in the decision you face. Remember that problems often mean different things in different perspectives. Relevant differences might include national expectations, organizational positions, disciplines, career trajectories, etc. Consider using the mnemonic device “Location, Knowledge, and Desire.”

Location : Who is defining the problem? Where are they located or how are they positioned? How do they get in their positions? Do you know anything about the history of their positions, and what led to the particular configuration of positions you have today on the job? Where are the key boundaries among different types of groups, and where are the alliances?

Knowledge : What forms of knowledge do the representatives of each perspective have? How do they understand the problem at hand? What are their assumptions? From what sources did they gain their knowledge? How did their knowledge evolve?

Desire : What do the proponents of each perspective want? What are their objectives? How do these desires develop? Where are they trying to go? Learn what you can about the history of the issue at hand. Who might have gained or lost ground in previous encounters? How does each perspective view itself at present in relation to those it envisions as relevant to its future?

As formal problem definitions emerge, ask “Whose definition is this?” Remember that “defining the problem clearly” may very well assert one perspective at the expense of others. Once we think about problem solving in relation to people, we can begin to see that the very act of drawing a boundary around a problem has non-technical, or political dimensions, depending on who controls the definition, because someone gains a little power and someone loses a little power.

Map what alternative problem definitions mean to different participants. More than likely you will best understand problem definitions that fit your perspective. But ask “Does it fit other perspectives as well?” Look at those who hold Perspective A. Does your definition fit their location, their knowledge, and their desires? Now turn to those who hold Perspective B. Does your definition fit their location, knowledge, and desires? Completing this step is difficult because it requires stepping outside of one’s own perspective and attempting to understand the problem in terms of different perspectives.

To the extent you encounter disagreement or conclude that the achievement of it is insufficient, begin asking yourself the following: How might I adapt my problem definition to take account of other perspectives out there? Is there some way of accommodating myself to other perspectives rather than just demanding that the others simply recognize the inherent value and rationality of mine? Is there room for compromise among contrasting perspectives?

How ‘good’ a solution do you need ¶

There is also an important aspect of real-world problem solving that is rarely articulated and that is the idea that the ‘quality’ of the analysis and the resources expended should be dependent on the context.

This is difficult to assess without some experience in the particular environment.

How ‘Good’ a Solution Do You Need?

Some rough examples:

10 second answer (answering a question at a meeting in front of your manager or vice president)

10 minute answer (answering a quick question from a colleague)

10 hour answer (answering a request from an important customer)

10 day answer (assembling information as part of a trouble-shooting team)

10 month answer (putting together a comprehensive portfolio of information as part of the design for a new $200,000,000 chemical plant)

Steps in solving well-defined engineering process problems, including textbook problems ¶

Essential steps:

Carefully read the problem statement (perhaps repeatedly) until you understand exactly the scenario and what is being asked.

Translate elements of the word problem to symbols. Also, look for key words that may convey additional information, e.g., ‘steady state’, ‘constant density’, ‘isothermal’. Make note of this additional information on your work page.

Draw a diagram. This can generally be a simple block diagram showing all the input, output, and connecting streams.

Write all known quantities (flow rates, densities, etc.) from step 2 in the appropriate locations on, or near, the diagram. If symbols are used to designate known quantities, include those symbols.

Identify and assign symbols to all unknown quantities and write them in the appropriate locations on, or near, the diagram.

Construct the relevant equation(s). These could be material balances, energy balances, rate equations, etc.

Write down all equations in their general forms. Don’t simplify anything yet.

Discard terms that are equal to zero (or are assumed negligible) for your specific problem and write the simplified equations.

Replace remaining terms with more convenient forms (because of the given information or selected symbols).

Construct equations to express other known relationships between variables, e.g., relationships between stoichiometric coefficients, the sum of species mass fractions must be one.

Whenever possible, solve the equations for the unknown(s) algebraically .

Convert the units of your variables as needed to have a consistent set across your equations.

Substitute these values into the equation(s) from step 7 to get numerical results.

Check your answer.

Does it make sense?

Are the units of the answer correct?

Is the answer consistent with other information you have?

Exercise: Checking results

How do you know your answer is right and that your analysis is correct?

This may be relatively easy for a homework problem, but what about your analysis for an ill-defined ‘real-world’ problem?

Want to create or adapt books like this? Learn more about how Pressbooks supports open publishing practices.

3 What is Problem Solving?

Chapter table of contents, what is problem solving.

- What Does Problem Solving Look Like?

Developing Problem Solving Processes

Summary of strategies, problem solving: an important job skill.

The ability to solve problems is a basic life skill and is essential to our day-to-day lives, at home, at school, and at work. We solve problems every day without really thinking about how we solve them. For example: it’s raining and you need to go to the store. What do you do? There are lots of possible solutions. Take your umbrella and walk. If you don’t want to get wet, you can drive, or take the bus. You might decide to call a friend for a ride, or you might decide to go to the store another day. There is no right way to solve this problem and different people will solve it differently.

Problem solving is the process of identifying a problem, developing possible solution paths, and taking the appropriate course of action.

Why is problem solving important? Good problem solving skills empower you not only in your personal life but are critical in your professional life. In the current fast-changing global economy, employers often identify everyday problem solving as crucial to the success of their organizations. For employees, problem solving can be used to develop practical and creative solutions, and to show independence and initiative to employers.

what does problem solving look like?

The ability to solve problems is a skill at which you can improve. So how exactly do you practice problem solving? Learning about different problem solving strategies and when to use them will give you a good start. Problem solving is a process. Most strategies provide steps that help you identify the problem and choose the best solution. There are two basic types of strategies: algorithmic and heuristic.

Algorithmic strategies are traditional step-by-step guides to solving problems. They are great for solving math problems (in algebra: multiply and divide, then add or subtract) or for helping us remember the correct order of things (a mnemonic such as “Spring Forward, Fall Back” to remember which way the clock changes for daylight saving time, or “Righty Tighty, Lefty Loosey” to remember what direction to turn bolts and screws). Algorithms are best when there is a single path to the correct solution.

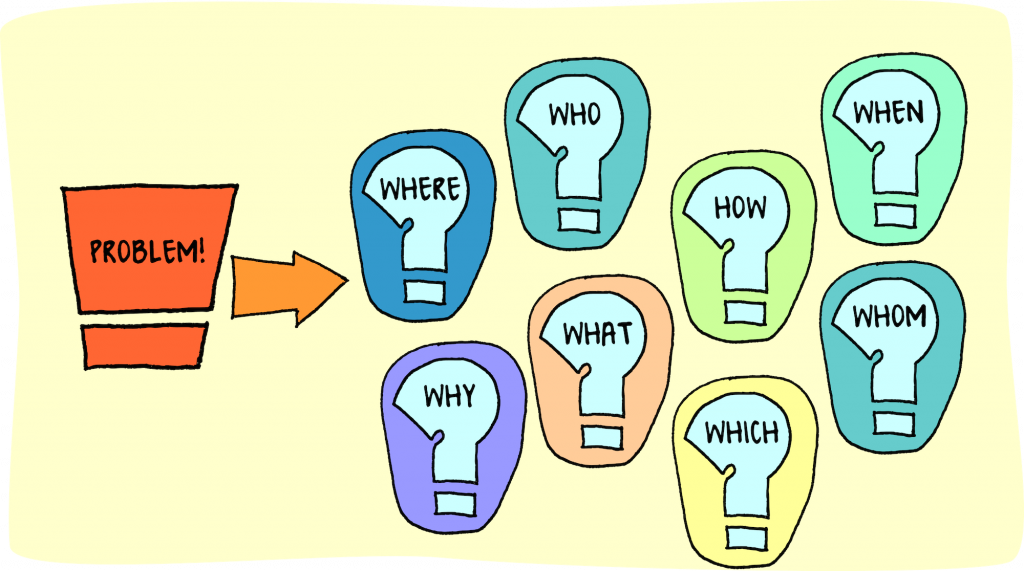

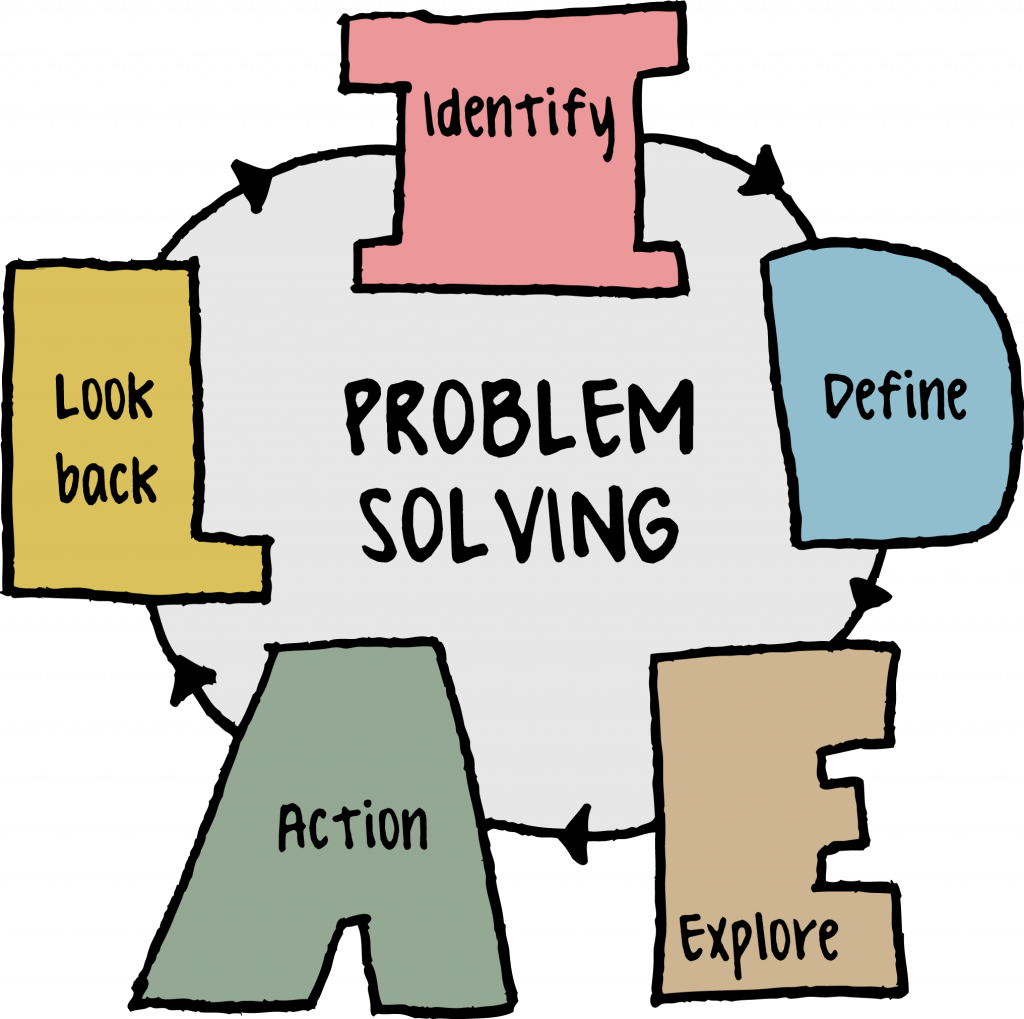

But what do you do when there is no single solution for your problem? Heuristic methods are general guides used to identify possible solutions. A popular one that is easy to remember is IDEAL [Bransford & Stein [1] ] :

IDEAL is just one problem solving strategy. Building a toolbox of problem solving strategies will improve your problem solving skills. With practice, you will be able to recognize and use multiple strategies to solve complex problems.

What is the best way to get a peanut out of a tube that cannot be moved? Watch a chimpanzee solve this problem in the video below [Geert Stienissen [2] ].

Problem solving is a process that uses steps to solve problems. But what does that really mean? Let's break it down and start building our toolbox of problem solving strategies.

What is the first step of solving any problem? The first step is to recognize that there is a problem and identify the right cause of the problem. This may sound obvious, but similar problems can arise from different events, and the real issue may not always be apparent. To really solve the problem, it's important to find out what started it all. This is called identifying the root cause .

Example: You and your classmates have been working long hours on a project in the school's workshop. The next afternoon, you try to use your student ID card to access the workshop, but discover that your magnetic strip has been demagnetized. Since the card was a couple of years old, you chalk it up to wear and tear and get a new ID card. Later that same week you learn that several of your classmates had the same problem! After a little investigation, you discover that a strong magnet was stored underneath a workbench in the workshop. The magnet was the root cause of the demagnetized student ID cards.

The best way to identify the root cause of the problem is to ask questions and gather information. If you have a vague problem, investigating facts is more productive than guessing a solution. Ask yourself questions about the problem. What do you know about the problem? What do you not know? When was the last time it worked correctly? What has changed since then? Can you diagram the process into separate steps? Where in the process is the problem occurring? Be curious, ask questions, gather facts, and make logical deductions rather than assumptions.

When issues and problems arise, it is important that they are addressed in an efficient and timely manner. Communication is an important tool because it can prevent problems from recurring, avoid injury to personnel, reduce rework and scrap, and ultimately, reduce cost, and save money. Although, each path in this exercise ended with a description of a problem solving tool for your toolbox, the first step is always to identify the problem and define the context in which it happened.

There are several strategies that can be used to identify the root cause of a problem. Root cause analysis (RCA) is a method of problem solving that helps people answer the question of why the problem occurred. RCA uses a specific set of steps, with associated tools like the “5 Why Analysis" or the “Cause and Effect Diagram,” to identify the origin of the problem, so that you can:

Once the underlying cause is identified and the scope of the issue defined, the next step is to explore possible strategies to fix the problem.

If you are not sure how to fix the problem, it is okay to ask for help. Problem solving is a process and a skill that is learned with practice. It is important to remember that everyone makes mistakes and that no one knows everything. Life is about learning. It is okay to ask for help when you don’t have the answer. When you collaborate to solve problems you improve workplace communication and accelerates finding solutions as similar problems arise.

One tool that can be useful for generating possible solutions is brainstorming . Brainstorming is a technique designed to generate a large number of ideas for the solution to a problem. The goal is to come up with as many ideas as you can, in a fixed amount of time. Although brainstorming is best done in a group, it can be done individually.

Depending on your path through the exercise, you may have discovered that a couple of your coworkers had experienced similar problems. This should have been an indicator that there was a larger problem that needed to be addressed.

In any workplace, communication of problems and issues (especially those that involve safety) is always important. This is especially crucial in manufacturing where people are constantly working with heavy, costly, and sometimes dangerous equipment. When issues and problems arise, it is important that they be addressed in an efficient and timely manner. Because it can prevent problems from recurring, avoid injury to personnel, reduce rework and scrap, and ultimately, reduce cost and save money; effective communication is an important tool..

One strategy for improving communication is the huddle . Just like football players on the field, a huddle is a short meeting with everyone standing in a circle. It's always important that team members are aware of how their work impacts one another. A daily team huddle is a great way to ensure that as well as making team members aware of changes to the schedule or any problems or safety issues that have been identified. When done right, huddles create collaboration, communication, and accountability to results. Impromptu huddles can be used to gather information on a specific issue and get each team member's input.

"Never try to solve all the problems at once — make them line up for you one-by-one.” — Richard Sloma

Problem solving improves efficiency and communication on the shop floor. It increases a company's efficiency and profitability, so it's one of the top skills employers look for when hiring new employees. Employers consider professional skills, such as problem solving, as critical to their business’s success.

The 2011 survey, "Boiling Point? The skills gap in U.S. manufacturing [3] ," polled over a thousand manufacturing executives who reported that the number one skill deficiency among their current employees is problem solving, which makes it difficult for their companies to adapt to the changing needs of the industry.

- Bransford, J. & Stein, B.S. (). The Ideal Problem Solver: A Guide For Improving Thinking, Learning, And Creativity . New York, NY: W.H. Freeman. ↵

- National Geographic. [Geert Stienissen]. (2010, August 19). Insight learning: Chimpanzee Problem Solving [Video file]. Retrieved from http://www.youtube.com/watch?v=fPz6uvIbWZE ↵

- Report: Boiling Point: The Skills Gap in U.S. Manufacturing Deloitte / The Manufacturing Institute, October 2011. Retrieved from http://www.themanufacturinginstitute.org/Hidden/2011-Skills-Gap-Report/2011-Skills-Gap-Report.aspx ↵

Introduction to Industrial Engineering Copyright © 2020 by Bonnie Boardman is licensed under a Creative Commons Attribution 4.0 International License , except where otherwise noted.

Share This Book

Engineering Problem-Solving

- First Online: 21 September 2022

Cite this chapter

- Michelle Blum 2

656 Accesses

You are becoming an engineer to become a problem solver. That is why employers will hire you. Since problem-solving is an essential portion of the engineering profession, it is necessary to learn approaches that will lead to an acceptable resolution. In real-life, the problems engineers solve can vary from simple single solution problems to complex opened ended ones. Whether simple or complex, problem-solving involves knowledge, experience, and creativity. In college, you will learn prescribed processes you can follow to improve your problem-solving abilities. Also, you will be required to solve an immense amount of practice and homework problems to give you experience in problem-solving. This chapter introduces problem analysis, organization, and presentation in the context of the problems you will solve throughout your undergraduate education.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

- Durable hardcover edition

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

https://www.merriam-webster.com/dictionary , viewed June 3, 2021.

Mark Thomas Holtzapple, W. Dan Reece (2000), Foundations of Engineering, McGraw-Hill, New York, New York, ISBN:978-0-07-029706-7.

Google Scholar

Aide, A.R., Jenison R.D., Mickelson, S.K., Northup, L.L., Engineering Fundamentals and Problem Solving, McGraw-Hill, New York, NY, ISBN: 978-0-07-338591-4.

Download references

Author information

Authors and affiliations.

Syracuse University, Syracuse, NY, USA

Michelle Blum

You can also search for this author in PubMed Google Scholar

End of Chapter Problems

1.1 ibl questions.

IBL1: Using standard problem-solving technique, answer the following questions

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, draw the vector representation of your path (hint: use a compass legend to help create your coordinate system)

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate the velocity you ran in the north direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate the velocity you ran in the east direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate how far you ran in the north direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate how far you ran in the east direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, how far north have you traveled in 5 min?

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, how far east have you traveled in 5 min?

What type of problem did you solve?

IBL2: For the following scenarios, explain what type of problem it is that needs to be solved.

Scientists hypothesize that PFAS chemicals in lawn care products are leading to an increase in toxic algae blooms in lakes during summer weather.

An engineer notices that a manufacturing machine motor hums every time the fluorescent floor lights are turned on.

The U.N. warns that food production must be increased by 60% by 2050 to keep up with population growth demand.

Engineers are working to identify and create viable alternative energy sources to combat climate change.

1.2 Practice Problems

Make sure all problems are written up using appropriate problem-solving technique and presentation.

The principle of conservation of energy states that the sum of the kinetic energy and potential energy of the initial and final states of an object is the same. If an engineering student was riding in a 200 kg roller coaster car that started from rest at 10 m above the ground, what is the velocity of the car when it drops to 2.5 m above the ground?

Archimedes’ principle states that the total mass of a floating object equals the mass of the fluid displaced by the object. A 45 cm cylindrical buoy is floating vertically in the water. If the water density is 1.00 g/cm 3 and the buoy plastic has a density of 0.92 g/cm 3 determine the length of the buoy that is not submerged underwater.

A student throws their textbook off a bridge that is 30 ft high. How long would it take before the book hits the ground?

Rights and permissions

Reprints and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this chapter

Blum, M. (2022). Engineering Problem-Solving. In: An Inquiry-Based Introduction to Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-91471-4_6

Download citation

DOI : https://doi.org/10.1007/978-3-030-91471-4_6

Published : 21 September 2022

Publisher Name : Springer, Cham

Print ISBN : 978-3-030-91470-7

Online ISBN : 978-3-030-91471-4

eBook Packages : Engineering Engineering (R0)

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

- EDUCATION & CAREER

- Engineering Books

- Science and Engineering Celebration Days

Tips for Solving Engineering Problems Effectively

Problem solving is the process of determining the best feasible action to take in a given situation. Problem solving is an essential skill for engineers to have. Engineers are problem solvers, as the popular quote says:

“Engineers like to solve problems. If there are no problems handily available, they will create their own problems.” – Scott Adams

Engineers are faced with a range of problems in their everyday life. The nature of problems that engineers must solve differs between and among the various disciplines of engineering. Because of the diversity of problems there is no universal list of procedures that will fit every engineering problem. Engineers use various approaches while solving problems.

Engineering problems must be approached systematically, applying an algorithm, or step-by-step practice by which one arrives at a feasible solution. In this post, we’ve prepared a list of tips for solving engineering problems effectively.

#1 Identify the Problem

Evaluating the needs or identifying the problem is a key step in finding a solution for engineering problems. Recognize and describe the problem accurately by exploring it thoroughly. Define what question is to be answered and what outputs or results are to be produced. Also determine the available data and information about the problem in hand.

An improper definition of the problem will cause the engineer to waste time, lengthen the problem solving process and finally arrive at an incorrect solution. It is essential that the stated needs be real needs.

As an engineer, you should also be careful not to make the problem pointlessly bound. Placing too many limitations on the problem may make the solution extremely complex and tough or impossible to solve. To put it simply, eliminate the unnecessary details and only keep relevant details and the root problem.

#2 Collect Relevant Information and Data

After defining the problem, an engineer begins to collect all the relevant information and data needed to solve the problem. The collected data could be physical measurements, maps, outcomes of laboratory experiments, patents, results of conducted surveys, or any number of other types of information. Verify the accuracy of the collected data and information.

As an engineer, you should always try to build on what has already been done before. Don’t reinvent the wheel. Information on related problems that have been solved or unsolved earlier, may help engineers find the optimal solution for a given problem.

#3 Search for Creative Solutions

There are a number of methods to help a group or individual to produce original creative ideas. The development of these new ideas may come from creativity, a subconscious effort, or innovation, a conscious effort.

You can try to visualize the problem or make a conceptual model for the given problem. So think of visualizing the given problem and see if that can help you gain more knowledge about the problem.

#4 Develop a Mathematical Model

Mathematical modeling is the art of translating problems from an application area into tractable mathematical formulations whose theoretical and numerical analysis provides insight, answers, and guidance useful for the originating application.

To develop a mathematical model for the problem, determine what basic principles are applicable and then draw sketches or block diagrams to better understand the problem. Then define and introduce the necessary variables so that the problem is stated purely in mathematical terms.

Afterwards, simplify the problem so that you can obtain the required result. Also identify the and justify the assumptions and constraints in the mathematical model.

#5 Use Computational Method

You can use a computational method based on the mathematical method you’ve developed for the problem. Derive a set of equations that enable the calculation of the desired parameters and variables as described in your mathematical model. You can also develop an algorithm, or step-by-step procedure of evaluating the equations involved in the solution.

To do so, describe the algorithm in mathematical terms and then execute it as a computer program.

#6 Repeat the Problem Solving Process

Not every problem solving is immediately successful. Problems aren’t always solved appropriately the first time. You’ve to rethink and repeat the problem solving process or choose an alternative solution or approach to solving the problem.

Bottom-line:

Engineers often use the reverse-engineering method to solve problems. For example, by taking things apart to identify a problem, finding a solution and then putting the object back together again. Engineers are creative , they know how things work, and so they constantly analyze things and discover how they work.

Problem-solving skills help you to resolve obstacles in a situation. As stated earlier, problem solving is a skill that an engineer must have and fortunately it’s a skill that can be learned. This skill gives engineers a mechanism for identifying things, figuring out why they are broken and determining a course of action to fix them.

Subscribe Now!

Get our latest news, eBooks, tutorials, and free courses straight into your inbox.

Types of Engineers and What they Do [Explained]

Latest innovations in civil engineering and construction industry, civil engineering: the hardest engineering degree.

- Education & Career 34

- Industry 24

- Technology 18

GET OUR APP

Engineering resources.

Is Electrical Engineering Hard? Here’s What You Need to Know

Disastrous engineering failures due to unethical practices of engineers, asme code of ethics for mechanical engineers, acm code of ethics for computing professionals.

Electrical and Computer Engineering Design Handbook

An Introduction to Electrical and Computer Engineering and Product Design by Tufts ECE Students

Problem Identification in Engineering Design

Problem identification is the first step of the engineering problem solving method. The relevant themes, processes and techniques for electrical engineering and their application to the senior design project are presented here.

Theory and Background

Engineering is a profession of applied science. Engineers must creatively find new ways to solve problems, and are always real-world problems. As a result, they are usually more complex than most problems studied in school, since many of the assumptions that are made to illustrate a concept are no longer valid. Yet, engineers still must come up with some solution. With so many new factors to consider when forming a solution, the entire process may seem daunting. In this way, one of the most critical steps in the problem solving process is solid problem identification. By effectively identifying the exact problem, and engineer may limit his or her focus to only the factors required to solve that problem (Shaw, 2001).

When inexperienced students go about the problem solving process, there are several paths they might take. For example, suppose students are building some type of robot. They have wired all their circuits together, but upon testing the robot, it simply does not work. The worst path they could take in this problem solving situation is to place all the blame upon factors out of their control. “The wires we have are faulty, so there is nothing we can do.” While this might be the case, it should be the last resort, as it leads to giving up on all prior work.

More motivated students might check several parts of their design and tinker with it until it works. This ad-hoc method is most common. The students can recall different ideas they have heard might cause problems, and check each one sequentially until a solution is found. In this manner, the problem identification is melded directly to the solution, as finding the latter leads to discovering the former. The difficulty with this ad-hoc method is that it varies with each project, so a more general system to fix problems cannot be extracted from this.

The best students may look at generalized problem solving methods that have been studied and improved upon for decades, and find a way to apply it to their project. This is the path that we will examine, and to do so, we will look at several example methods.

Common Themes

The similarities among the problem solving methods can be seen across many industries, especially business. Even with no scientific or technical aspects to a situation, the same ideas identify the problems effectively. One main cause for the similarities is the desire in business and other fields to have a rigorous methodology aimed at improving the target idea, project, company, etc.

To look at some common themes in problem solving methods, we will compare four widely used techniques: the TRIZ method, Root Cause Failure Analysis, and the two methods described in How to Solve It by Pólya (1957).

TRIZ Method

TRIZ, which is a Russian acronym for Theory of Inventive Problem Solving , is a problem solving method based on the study of patterns in problems and solutions. The developers of this method have analyzed over three million inventions with the intent of predicting where breakthroughs will come from (Jugulum & Samuel, 2008). The idea is that problems and solutions are repeated across a wide variety of applications, so by generalizing the problem, one can find a proven solution. Once the abstracted problem has been solved, the solution must then be adapted to the specific situation.

This method, like many other problem solving methods, is an iterative process. Identifying the problem is the first step. Once all the TRIZ analysis tools have been used and a solution has been identified, the process cycles back to identification again. Any new factors that arise from the initial solution must be addressed and attacked in the same manner as the original situation.

The main tool of classical TRIZ analysis for problem definition is the contradiction matrix. The axes of the matrix are engineering parameters, and potential general solutions are filled in the boxes. When one solution leads to a larger problem, a contradiction is identified. Kutz describes the tool:

The objective of the matrix is to direct the problem-solving process to incorporate an idea that has been utilized before to solve an analogous ‘‘inventive’’ problem. The contradiction matrix accomplishes this by asking two simple questions: Which element of the system is in need of improvement? If improved, which element of the system is deteriorated?” (Kutz, 2006, p. 622)

This is a useful tool if the design process is certain to be a long and iterative one. By going through such exhaustive planning and searching in the beginning, one can cut down many iterations in the process. However, the tool falls short if the scope is problem. It simply may not be necessary to write out the entire matrix for a problem that has only a few clear parameters to it.

Root Cause Failure Analysis

In reliability engineering and quality control, the main objective is to deal with problems and failures. It seems clear that a systematic approach to identifying the problem would arise in this field. This is the aim of Root Cause Failure Analysis (RFCA) (Mobley, 1999). The main idea is to identify the root cause of the problem that arises and eliminate it, as opposed to waiting for effects and mitigating them. It is analogous to getting vaccinated for the flu instead of waiting to catch it and then buying tissues.

There are several analysis techniques used in RFCA. These include Failure Mode and Effects Analysis, Cause and Effect Analysis, also known as fishbone analysis, and Sequence of Events Analysis. The applicability of each technique depends on what type of problem is present and what you want to focus on. For example, when the problem arose over time, the sequence analysis might be best. Alternatively, when you just want to lay out all possible causes without giving weight to any, the fishbone analysis is useful. A diagram of fishbone analysis is shown in Figure 1.

Fishbone Analysis.

The main issue unique to RFCA is the high cost of performing such an analysis (Mobley,1999). This means it should be used only when it is absolutely necessary. Also, it is somewhat limited in scope, as it was originally designed for use in chemical plant analysis.

How to Solve It

The book How to Solve It , written in 1957 by mathematician George Pólya, gives the methods used to solve many math problems and abstracts them to general problems. He generally describes the steps as understanding the problem, making a plan, carrying it out, and analyzing.

One of the most useful ideas he puts forth that is widely used in mathematics is to find an analogous problem and solve it. This is more useful in the extremely abstract world of mathematics where assumptions always hold true and objects are perfect, but the technique can be used to get a good approximation of a real world problem. In the world of engineering, this may be sufficient to get the job done.

While the techniques outlined in the book are very interesting to me as a mathematician, there are times when the methods can fall short. It is good practice to see how rigorous problem identifications and solutions can be generalized, but that is the majority of what the method does. To go out and solve your specific problem, there are still many specific connections to be made.

Application to Senior Project

The problem identification process is critical to the senior design project’s success. Before any design, implementation, or even productive planning can be done, the central problems behind the project must be laid out. This process goes hand in hand with identifying customer specifications. It is always critical to know precisely what the customer wants; however, in the ECE senior design projects , where student have essentially no prior experience, this step should get special care. See Ulrich & Eppinger (2004) for more information on customer specifications.

Once the customer’s needs and desires have been finalized, the problem identification may begin. There will almost certainly be multiple areas of the project that have a main problem. As you look at all the items the customer has suggested or demanded, you may find contradicting qualities. Here is where breaking the problem down to its most basic form is crucial. Only then can engineering decisions be made about which areas to compromise for the good of the whole project.

While the customer specification process only should occur once, the problem identification occurs many times as the design process is iterated. For example, in the Red Team’s senior project , which involved modifying a Parrot AR Drone toy helicopter to be able to autonomously collect data, the first major problem was finding usable and inexpensive hardware to add (Video 1). Once that had been solved, the next problem area was designing software that would allow the drone to hover stably at a target. Initially these two problems appeared to be the largest challenges; however, upon completing preliminary testing, it was discovered that no matter how sophisticated the stabilizing algorithm became, the helicopter would not remain very stable. As a result, the problem solving branched out in a direction previously unexpected. The process of identifying this new problem led to a workable solution.

The Red Team’s autonomous drone project navigating and gathering data. Source: Tufts SPARTN Channel on YouTube.com.

Cited References

- Jugulum, R., & Samuel, P. (2008). Design for Lean Six Sigma – A Holistic Approach to Design and Innovation . Hoboken: John Wiley & Sons. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/637224080

- Kutz, M. (2006). Mechanical Engineers’ Handbook – Materials and Mechanical Design (3rd ed.). Hoboken: John Wiley & Sons. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/59003354

- Mobley, R.K. (1999). Root Cause Failure Analysis . Boston: Newnes/Elsevier. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/40255833

- Pólya, G. (1957). How to Solve It . Garden City, NY: Doubleday. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/523312

- Shaw, M. C. (2001). Engineering Problem Solving – A Classical Perspective . Norwich: William Andrew Publishing/Noyes. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/633151037

Additional Sources / Recommended Reading

- Ulrich, K. T. & Eppinger, S. D. (2004). Product Design and Development . Boston/New York: McGraw-Hill/ Irwin. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/122424997

- ← Fuzzy Front-End

- Intellectual Property →

Disclaimer | Non-Discrimination | Privacy | Terms for Creating and Maintaining Sites

FREE K-12 standards-aligned STEM

curriculum for educators everywhere!

Find more at TeachEngineering.org .

- TeachEngineering

- Solving Everyday Problems Using the Engineering Design Cycle

Hands-on Activity Solving Everyday Problems Using the Engineering Design Cycle

Grade Level: 7 (6-8)

(two 60-minutes class periods)

Additional materials are required if the optional design/build activity extension is conducted.

Group Size: 4

Activity Dependency: None

Subject Areas: Science and Technology

NGSS Performance Expectations:

TE Newsletter

Engineering connection, learning objectives, materials list, worksheets and attachments, introduction/motivation, vocabulary/definitions, investigating questions, activity extensions, user comments & tips.

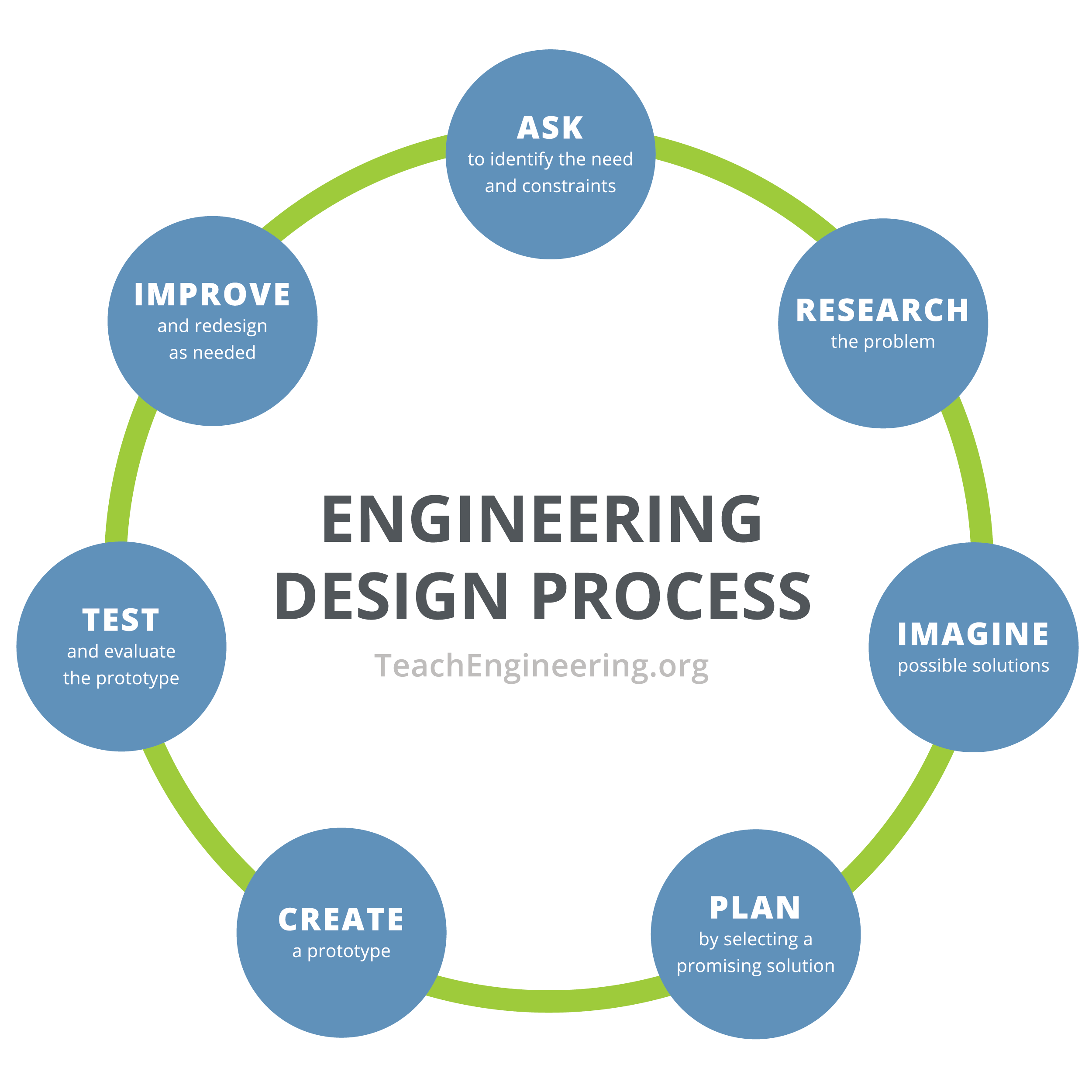

This activity introduces students to the steps of the engineering design process. Engineers use the engineering design process when brainstorming solutions to real-life problems; they develop these solutions by testing and redesigning prototypes that work within given constraints. For example, biomedical engineers who design new pacemakers are challenged to create devices that help to control the heart while being small enough to enable patients to move around in their daily lives.

After this activity, students should be able to:

- Explain the stages/steps of the engineering design process .

- Identify the engineering design process steps in a case study of a design/build example solution.

- Determine whether a design solution meets the project criteria and constraints.

- Think of daily life situations/problems that could be improved.

- Apply the engineering design process steps to develop their own innovations to real-life problems.

- Apply the engineering design cycle steps to future engineering assignments.

Educational Standards Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards. All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN) , a project of D2L (www.achievementstandards.org). In the ASN, standards are hierarchically structured: first by source; e.g. , by state; within source by type; e.g. , science or mathematics; within type by subtype, then by grade, etc .

Ngss: next generation science standards - science.

| NGSS Performance Expectation | ||

|---|---|---|

| MS-ETS1-1. Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. (Grades 6 - 8) Do you agree with this alignment? Thanks for your feedback! | ||

| This activity focuses on the following aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a design problem that can be solved through the development of an object, tool, process or system and includes multiple criteria and constraints, including scientific knowledge that may limit possible solutions. Alignment agreement: Thanks for your feedback! | The more precisely a design task's criteria and constraints can be defined, the more likely it is that the designed solution will be successful. Specification of constraints includes consideration of scientific principles and other relevant knowledge that is likely to limit possible solutions. Alignment agreement: Thanks for your feedback! | All human activity draws on natural resources and has both short and long-term consequences, positive as well as negative, for the health of people and the natural environment. Alignment agreement: Thanks for your feedback! The uses of technologies and any limitations on their use are driven by individual or societal needs, desires, and values; by the findings of scientific research; and by differences in such factors as climate, natural resources, and economic conditions.Alignment agreement: Thanks for your feedback! |

| NGSS Performance Expectation | ||

|---|---|---|

| MS-ETS1-4. Develop a model to generate data for iterative testing and modification of a proposed object, tool, or process such that an optimal design can be achieved. (Grades 6 - 8) Do you agree with this alignment? Thanks for your feedback! | ||

| This activity focuses on the following aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Develop a model to generate data to test ideas about designed systems, including those representing inputs and outputs. Alignment agreement: Thanks for your feedback! | Models of all kinds are important for testing solutions. Alignment agreement: Thanks for your feedback! The iterative process of testing the most promising solutions and modifying what is proposed on the basis of the test results leads to greater refinement and ultimately to an optimal solution.Alignment agreement: Thanks for your feedback! | |

International Technology and Engineering Educators Association - Technology

View aligned curriculum

Do you agree with this alignment? Thanks for your feedback!

State Standards

Massachusetts - science.

Each group needs:

- Marisol Case Study , one per student

- Group Leader Discussion Sheet , one per group

To share with the entire class:

- computer/projector setup to show the class the Introduction to the Engineering Design Cycle Presentation , a Microsoft® PowerPoint® file

- paper and pencils

- (optional) an assortment of scrap materials such as fabric, super glue, wood, paper, plastic, etc., provided by the teacher and/or contributed by students, to conduct the hands-on design/build extension activity

(Have the 19-slide Introduction to the Engineering Design Cycle Presentation , a PowerPoint® file, ready to show the class.)

Have you ever experienced a problem and wanted a solution to it? Maybe it was a broken backpack strap, a bookshelf that just kept falling over, or stuff spilling out of your closet? (Let students share some simple problems with the class). With a little bit of creativity and a good understanding of the engineering design process, you can find the solutions to many of these problems yourself!

But what is the engineering design process? (Listen to some student ideas shared with the class.) The engineering design process, or cycle, is a series of steps used by engineers to guide them as they solve problems.

(Show students the slide presentation. Refer to the notes under each slide for a suggested script and comments. The slides introduce the main steps of the engineering design process, and walk through a classroom problem—a teacher’s disorganized desk that is preventing timely return of graded papers—and how students devise a solution. It also describes the work of famous people—Katherine Johnson, Lee Anne Walters, Marc Edwards, James E. West and Jorge Odón—to illustrate successful examples of using the steps of the engineering design process.)

Now that we’ve explore the engineering design process, let’s see if we can solve a real-world problem. Marisol is a high-school student who is very excited to have their own locker. They have lots of books, assignments, papers and other items that they keep in their locker. However, Marisol is not very organized. Sometimes they are late to class because they need extra time to find things that were stuffed into their locker. What is Marisol’s problem? (Answer: Their locker is disorganized.) In your groups, you’ll read through Marisol’s situation and see how they use the engineering design process to solve it. Let’s get started!

This activity is intended as an introduction to the engineering design cycle. It is meant to be relatable to students and serve as a jumping off point for future engineering design work.

Engineers follow the steps of the engineering design process to guide them as they solve problems. The steps shown in Figure 1 are:

Ask: identify the need & constraints

- Identify and define the problem. Who does the problem affect? What needs to be accomplished? What is the overall goal of the project?

- Identify the criteria and constraints. The criteria are the requirements the solution must meet, such as designing a bag to hold at least 10 lbs. Constraints are the limitations and restrictions on a solution, such as a maximum budget or specific dimensions.

Research the problem

- Learn everything you can about the problem. Talk to experts and/or research what products or solutions already exist.

- If working for a client, such as designing new filters for a drinking water treatment plant, talk with the client to determine the needs and wants.

Imagine: develop possible solutions

- Brainstorm ideas and come up with as many solutions as possible. Wild and crazy ideas are welcome! Encourage teamwork and building on ideas.

Plan: select a promising solution

- Consider the pros and cons of all possible solutions, keeping in mind the criteria and constraints.

- Choose one solution and make a plan to move forward with it.

Create: build a prototype

- Create your chosen solution! Push for creativity, imagination and excellence in the design.

Test and evaluate prototype

- Test out the solution to see how well it works. Does it meet all the criteria and solve the need? Does it stay within the constraints? Talk about what worked during testing and what didn’t work. Communicate the results and get feedback. What could be improved?

Improve: redesign as needed

- Optimize the solution. Redesign parts that didn’t work, and test again.

- Iterate! Engineers improve their ideas and designs many times as they work towards a solution.

Some depictions of the engineering design process delineate a separate step—communication. In the Figure 1 graphic, communication is considered to be incorporated throughout the process. For this activity, we call out a final step— communicate the solution —as a concluding stage to explain to others how the solution was designed, why it is useful, and how they might benefit from it. See the diagram on slide 3.

For another introductory overview of engineering and design, see the What Is Engineering? What Is Design? lesson and/or show students the What Is Engineering? video.

Before the Activity

- Make copies of the five-page Marisol Case Study , one per student, and the Group Leader Discussion Sheet , one per group.

- Be ready to show the class the Introduction to the Engineering Design Cycle Presentation , a PowerPoint® file.

With the Students

- As a pre-activity assessment, spend a few minutes asking students the questions provided in the Assessment section.

- Present the Introduction/Motivation content to the class, which includes using the slide presentation to introduce students to the engineering design cycle. Throughout, ask for their feedback, for example, any criteria or constraints that they would add, other design ideas or modifications, and so forth.

- Divide the class into groups of four. Ask each team to elect a group leader. Hand out the case study packets to each student. Provide each group leader with a discussion sheet.

- In their groups, have students work through the case study together.

- Alert students to the case study layout with its clearly labeled “stop” points, and direct them to just read section by section, not reading beyond those points.

- Suggest that students either taking turns reading each section aloud or read each section silently.

- Once all students in a group have read a section, the group leader refers to the discussion sheet and asks its questions of the group, facilitating a discussion that involves every student.

- Encourage students to annotate the case study as they like; for example, they might note in the margins Marisol’s stage in the design process at various points.

- As students work in their groups, walk around the classroom and encourage group discussion. Ensure that each group member contributes to the discussion and that group members are focused on the same section (no reading ahead).

- After all teams have finished the case study and its discussion questions, facilitate a class discussion about how Marisol used the engineering design cycle. This might include referring back to questions 4 and 5 in “Stop 5” to discuss remaining questions about the case study and relate the case study example back to the community problems students suggested in the pre-activity assessment.

- Administer the post-activity assessment.

brainstorming: A team creativity activity with the purpose to generate a large number of potential solutions to a design challenge.

constraint: A limitation or restriction. For engineers, design constraints are the requirements and limitations that the final design solutions must meet. Constraints are part of identifying and defining a problem, the first stage of the engineering design cycle.

criteria: For engineers, the specifications and requirements design solutions must meet. Criteria are part of identifying and defining a problem, the first stage of the engineering design cycle.

develop : In the engineering design cycle, to create different solutions to an engineering problem.

engineering: Creating new things for the benefit of humanity and our world. Designing and building products, structures, machines and systems that solve problems. The “E” in STEM.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products or systems. The process is cyclical and iterative. Also called the engineering design cycle.

evaluate: To assess something (such as a design solution) and form an idea about its merit or value (such as whether it meets project criteria and constraints).

optimize: To make the solution better after testing. Part of the engineering design cycle.

Pre-Activity Assessment

Intro Discussion: To gauge how much students already know about the activity topic and start students thinking about potential design problems in their everyday lives, facilitate a brief class discussion by asking students the following questions:

- What do engineers do? (Example possible answers: Engineers design things that help people, they design/build/create new things, they work on computers, they solve problems, they create things that have never existed before, etc.)

- What are some problems in your home, school or community that could be solved through engineering? (Example possible answers: It is too dark in a community field/park at night, it is hard to carry shopping bags in grocery store carts, the dishwasher does not clean the dishes well, we spend too much time trying to find shoes—or other items—in the house/garage/classroom, etc.)

- How do engineers solve problems? (Example possible answers: They build new things, design new things, etc. If not mentioned, introduce students to the idea of the engineering design cycle. Liken this to how research scientists are guided by the steps of the scientific method.)

Activity Embedded Assessment

Small Group Discussions: As students work, observe their group discussions. Make sure the group leaders go through all the questions for each section, and that each group member contributes to the discussions.

Post-Activity Assessment

Marisol’s Design Process: Provide students with writing paper and have them write “Marisol’s Design Process” at the top. Direct them to clearly write out the steps that Marisol went through as they designed and completed their locker organizer design and label them according to where they fit in the engineering design cycle. For example, “Marisol had to jump back to avoid objects falling out of their locker” and they stated a desire to “wanted to find a way to organize their locker” both illustrate the “identifying the problem” step.

- Which part of the engineering design cycle is Marisol working on as they design an organizer?

- Why is it important to identify the criteria and constraints of a project before building and testing a prototype? (Example possible answers: So that the prototype will be the right size, so that you do not go over budget, so that it will solve the problem, etc.)

- Why do engineers improve and optimize their designs? (Example possible answers: To make it work better, to fix unexpected problems that come up during testing, etc.)

To make this a more hands-on activity, have students design and build their own locker organizers (or other solutions to real-life problems they identified) in tandem with the above-described activity, incorporating the following changes/additions to the process:

- Before the activity: Inform students that they will be undertaking an engineering design challenge. Without handing out the case study packet, introduce students to Marisol’s problem: a disorganized locker. Ask students to bring materials from home that they think could help solve this problem. Then, gather assorted materials (wood and fabric scraps, craft materials, tape, glue, etc.) to provide for this challenge, giving each material a cost (for example, wood pieces cost 50¢, fabric costs 25¢, etc.) and write these on the board or on paper to hand out to the class.

- Present the Introduction/Motivation content and slides to introduce students to the engineering design process (as described above). Then have students go through the steps of the engineering design process to create a locker organizer for Marisol. Inform them Marisol has only $3 to spend on an organizer, so they must work within this budget constraint. As a size constraint, tell students the locker is 32 inches tall, 12 inches wide and 9.5 inches deep. (Alternatively, have students measure their own lockers and determine the size themselves.)

- As students work, ask them some reflection questions such as, “Which step of the engineering design process are you working on?” and “Why have you chosen that solution?”

- Let groups present their organizers to the class and explain the logic behind their designs.

- Next, distribute the case study packet and discussion sheets to the student groups. As the teams read through the packet, encourage them to discuss the differences between their design solutions and Marisol’s. Mention that in engineering design there is no one right answer; rather, many possible solutions may exist. Multiple designs may be successful in imagining and fabricating a solution that meets the project criteria and constraints.

Engineering Design Process . 2014. TeachEngineering, Web. Accessed June 20, 2017. https://www.teachengineering.org/k12engineering/designprocess

Contributors

Supporting program, acknowledgements.

This material is based upon work supported by the National Science Foundation CAREER award grant no. DRL 1552567 (Amy Wilson-Lopez) titled, Examining Factors that Foster Low-Income Latino Middle School Students' Engineering Design Thinking in Literacy-Infused Technology and Engineering Classrooms. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: October 26, 2023

What Is Problem Solving? How Software Engineers Approach Complex Challenges

From debugging an existing system to designing an entirely new software application, a day in the life of a software engineer is filled with various challenges and complexities. The one skill that glues these disparate tasks together and makes them manageable? Problem solving .

Throughout this blog post, we’ll explore why problem-solving skills are so critical for software engineers, delve into the techniques they use to address complex challenges, and discuss how hiring managers can identify these skills during the hiring process.

What Is Problem Solving?

But what exactly is problem solving in the context of software engineering? How does it work, and why is it so important?

Problem solving, in the simplest terms, is the process of identifying a problem, analyzing it, and finding the most effective solution to overcome it. For software engineers, this process is deeply embedded in their daily workflow. It could be something as simple as figuring out why a piece of code isn’t working as expected, or something as complex as designing the architecture for a new software system.

In a world where technology is evolving at a blistering pace, the complexity and volume of problems that software engineers face are also growing. As such, the ability to tackle these issues head-on and find innovative solutions is not only a handy skill — it’s a necessity.

The Importance of Problem-Solving Skills for Software Engineers

Problem-solving isn’t just another ability that software engineers pull out of their toolkits when they encounter a bug or a system failure. It’s a constant, ongoing process that’s intrinsic to every aspect of their work. Let’s break down why this skill is so critical.

Driving Development Forward

Without problem solving, software development would hit a standstill. Every new feature, every optimization, and every bug fix is a problem that needs solving. Whether it’s a performance issue that needs diagnosing or a user interface that needs improving, the capacity to tackle and solve these problems is what keeps the wheels of development turning.

It’s estimated that 60% of software development lifecycle costs are related to maintenance tasks, including debugging and problem solving. This highlights how pivotal this skill is to the everyday functioning and advancement of software systems.

Innovation and Optimization

The importance of problem solving isn’t confined to reactive scenarios; it also plays a major role in proactive, innovative initiatives . Software engineers often need to think outside the box to come up with creative solutions, whether it’s optimizing an algorithm to run faster or designing a new feature to meet customer needs. These are all forms of problem solving.